Hot dip galvanized steel is becoming increasingly popular in contemporary architecture as an aesthetic feature as well as being used for its functional properties.

Hot Dip Galvanizers Association of South Africa (HDGASA) executive director Robin Clarke says this has created a developing market for the galvanizing sector which the HDGASA represents.

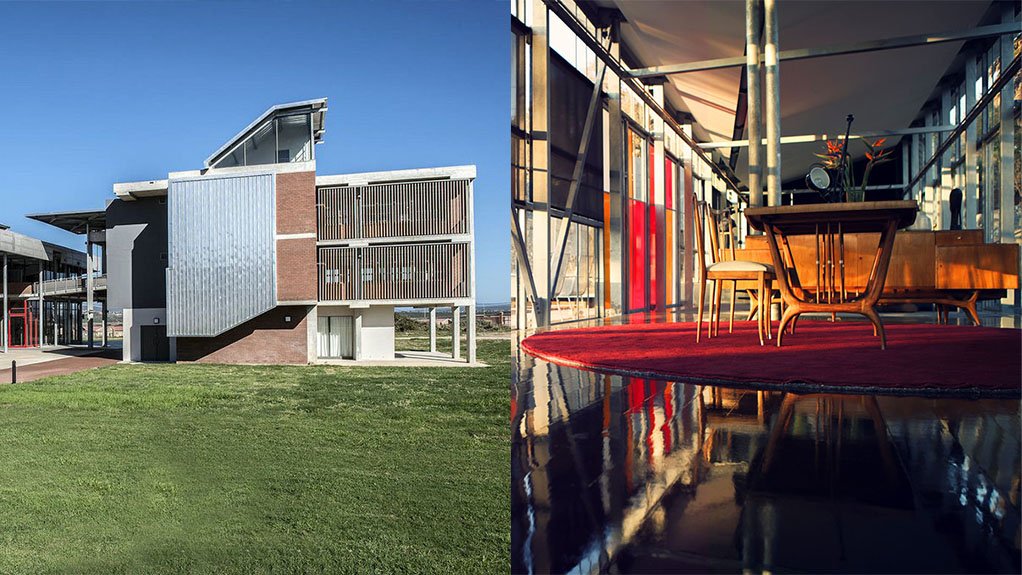

Galvanized steel is used by architects and designers to create steel frames, skeletons and steel facades, leaving structural steel exposed and highlighting the internal elements of buildings.

“The Glass House in Parktown North is an example of this. Designed by architect Karlien Thomashoff and artist / owner Roelof Petrus van Wyk, it was inspired by Johannesburg’s rich gold mining history. The surrounding buildings - and the hot dip galvanized steel electricity pylons located a few metres away from the site - add to this industrial aesthetic,” Clarke explains.

Architecture has also embraced sustainability, smart construction and the reuse of building materials, notes Clarke, adding: “Architects have followed trends such as the optimal utilisation of space, and the ability to reuse materials. All of these elements have come together and sparked a move towards designing for sustainability.”

Clarke highlights the new Tram Street offices in Pretoria where custom-designed galvanized planters and drain pipes have been integrated with softer textures and green foliage as an example of how galvanized steel can be used in conjunction with other natural materials.

A sun control structure on the northern and southern facades of the building was also made out of hot dip galvanized steel. The entrance canopy of the office block is framed with a horizontal hot dip galvanized channel supported from the building, giving the illusion of a floating roof.

Clarke explains that existing standards SANS 121 cover baseline hot dip galvanizing requirements for corrosion contro,l but architects that require galvanized steel for aesthetics beyond this requirement must work closely with fabricators and galvanizers to ensure that the fabricated steel sections comply with SANS 14713 Parts 1 and 2.

The HDGASA asserts that it plays a valuable role in providing guidance, ensuring that the responsibility to fabricate in a compliant manner is shared across the supply chain.

This includes advising architects and designers on the correct quality of steel selected for galvanizing: “In this regard, support from a fabricator working to a high standard will ensure that a galvanizer can deliver extra smoothness, with no lumps and bumps around the bolt holes, no oxide lines and also adequate provision for drainage holes,” Clarke advises.

“In this manner, hot dip galvanizing very successfully blends elements such as steel, glass and concrete into a strong architectural statement: coherent, appealing and sustainable; and also fulfils an accentuating and framing function – over and above its inherent properties of corrosion control and long service life,” Clarke concludes.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here