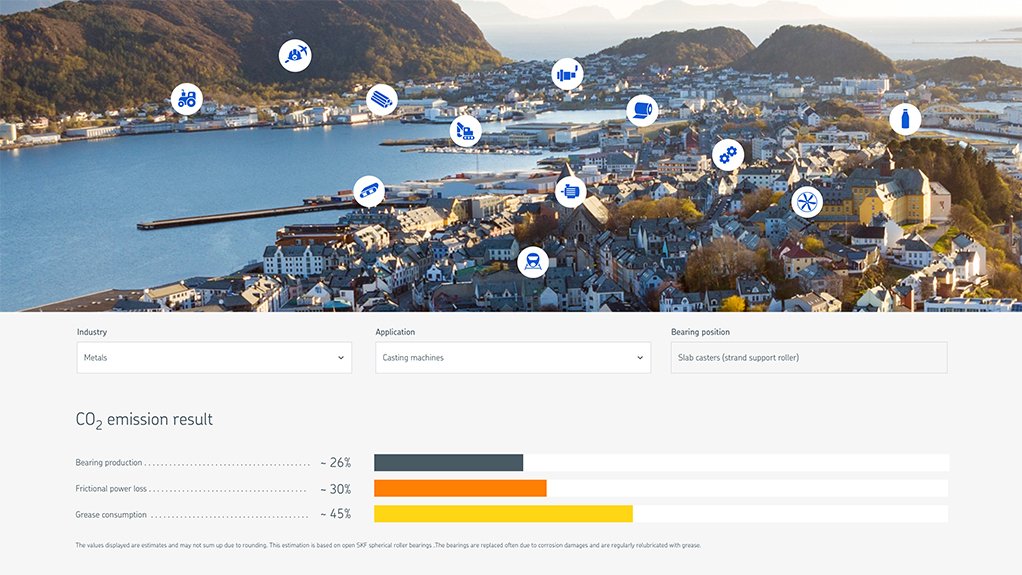

A freely available dashboard has recently been launched, allowing users to explore how carbon dioxide (CO2) emissions related to the production and use of bearings are distributed in different industries. The tool provides illustrative examples based on how emissions differ in various positions across industry applications.

SKF introduced the new dashboard to help industry understand and address carbon emissions.

Users can also get a more detailed estimation with SKF’s Bearing Select software tool by adding a few data points. The user receives the estimated CO2 emissions for single rolling bearing, illustrating estimated emissions related to the production phase and from frictional power losses and grease consumption when in operation. A report can be downloaded to give details on the estimations, which can provide a starting point for improving the application for enhanced sustainability performance.

The tool offers the opportunity for users to engage with SKF’s expert application engineers, who can provide a detailed view of the specific carbon emissions for the bearings and how the customer’s application can be optimised to reduce energy consumption and corresponding emissions in the future.

“Ultimately, improving the sustainability performance of a customer application requires the understanding of the full life cycle based on specific application data. I believe the tool we are launching will make it easier and more tangible for our customers to understand and accelerate this journey” said SKF head of sustainability Johan Lannering.

Users can select options for calculations in a range of application areas, including industrial, metals, mining, mineral processing, cement, railways, fluid machinery, material handling and industrial electrical, with more industries planned for inclusion in the future.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here