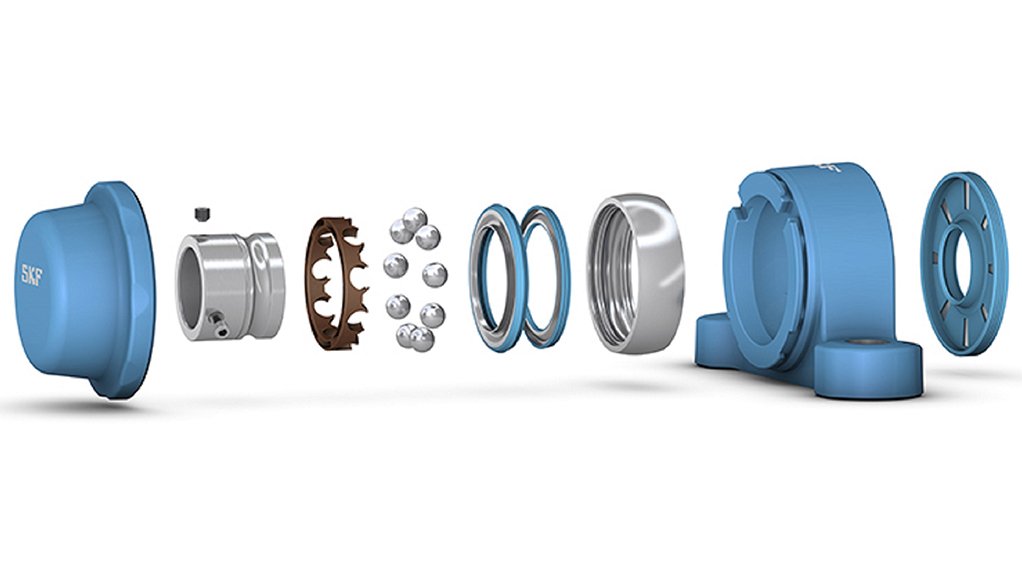

A range of food-line ball bearing units that include hygienically designed components, offer improved reliability, reduced maintenance costs and increased sustainability for food and beverage companies.

Bacterial contamination and undeclared allergens are said to represent the majority of causes of US Food and Drug Administration food recalls, making proactive food safety a priority for the food and beverage industry.

“The problem is, traditional relubrication, wash-downs and dry cleaning of bearings can create hidden means by which contaminants thrive, such as airborne droplets, wastewater, or contaminated grease,” says SKF innovation and business development chief technical officer and president Victoria van Camp.

SKF’s Blue Range of food-line ball bearings are designed to improve hygiene, reliability, performance and compliance with food safety regulations, while reducing maintenance costs for food and beverage companies.

The sealing system and high-performance bearing grease used in the units aim to improve the performance and hygiene of food processing equipment. The hygienic design makes the bearing units easier to clean and longer-lasting, reducing the risk of bacteria build-up in difficult-to-clean areas and minimising the spread of bacteria during cleaning. In addition, the bearing units do not require relubrication, reducing production stoppages to lubricate and clean equipment.

The units also aim to reduce environmental waste, with less hot water required for cleaning, less grease deposited in waste water and fully-recyclable components.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here