Pumps supplier, testing and servicing expert AESPUMP intends to further expand its apprenticeship programme, which it says is at the heart of its recent upgrade to Level 4 black economic- empowerment (BEE) accreditation.

“We believe that this emphasis on skills development will, over time, lead to a self-correction of black ownership,” AES Group GM and company secretary Craig Murray tells Mining Weekly.

He adds, however, that this will not happen overnight. The management of AESPUMP sister company ASSEAL believes that its active apprenticeship programme is already delivering a return on investment, citing the absorption of learners into the company’s workforce.

AESSEAL’s BEE rating became effective on September 2015, after its BEE certification had been reassessed upward from Level 5, owing to the company’s apprenticeship programme.

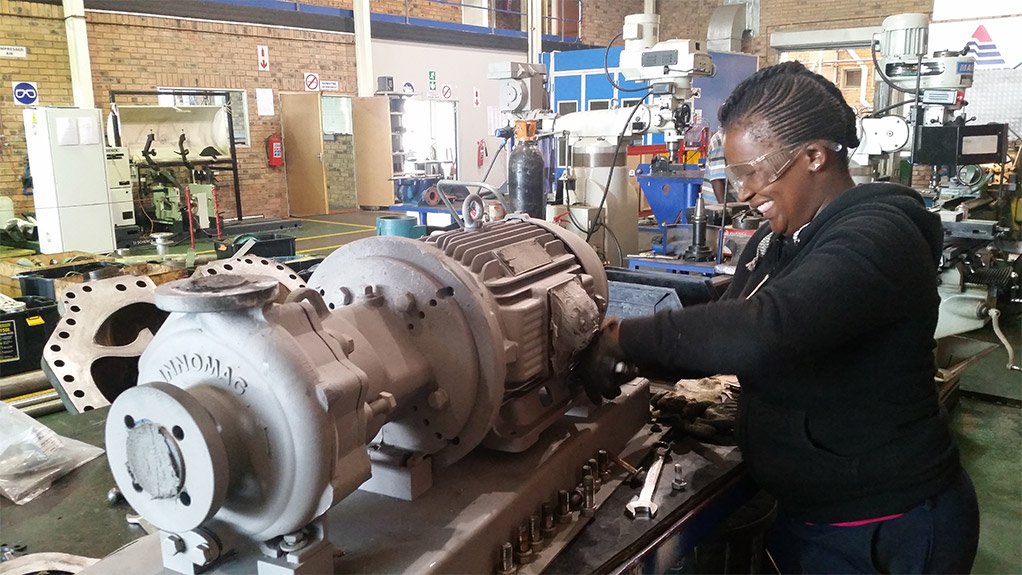

The companies employ a combined workforce of about 110 employees, with seven active apprentices currently undergoing alternate terms of theoretical training at Dinyane Education, in Secunda, Mpumalanga.

On-the-job mentorship at the company’s Secunda workshops ensures a steady stream of qualified fitters and turners after the completion of the two-year apprenticeship programme.

“Building up peoples’ skills over the long term from the initial stages is ultimately what we want to achieve through investment we have made in the apprenticeship programme,” adds Murray.

Such programmes will help companies meet government’s BEE targets in the medium term.

Regulations under the Preferential Procurement Policy Framework Act of 2000 have resulted in the reconfiguring of the BEE-certification codes, shifting emphasis from mere BEE compliance towards BEE strategy and true company empowerment, Murray notes.

He explains that the new BEE codes award only five points when a company spends as much as 80% of its procurement spend with suppliers who have a BEE certificate, whereas previously, between 12 and 15 points were awarded for a procurement spend lower than 70% involving BEE-certified suppliers.

Service Offerings

AESPUMP’s test bay allows for the accurate measurement of a pump’s performance and to supply the customer with a performance curve that shows precisely how that pump is performing.

If the test curve is not up to original- equipment manufacturer specification, AESPUMP specifies exactly what needs to be done and how much it will cost to get the pump back to specification.

AESPUMP’s Secunda facility is ISO 9001-, ISO 14001- and OSHAS 18001-accredited, has Mining and Surface Certification and SANS 60079-01/1 flame-proofing certification electric apparatus for explosive gas atmospheres, including OD 014 and OD 015. Repaired units comply fully with all health and safety legislation, assures the company.

Edited by: Tracy Hancock

Creamer Media Contributing Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here