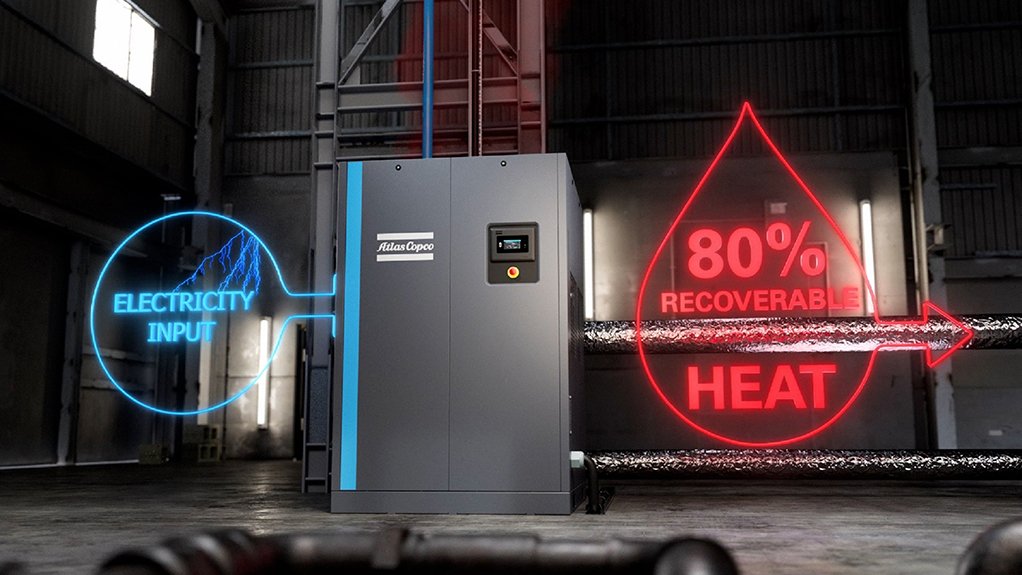

Compressed air is a key component of many manufacturing or processing operations and it is also recognised as one of the largest consumers of a plant’s energy, contributing to overall costs and emissions. Approximately 94% of the energy that is consumed by an air compressor is converted into heat which is subsequently released through the cooling system and radiation.

Atlas Copco has designed an energy recovery system that aims to recover wasted heat, transferring it to other areas in a plant where it can be re-used for various applications.

“With our ER 90-900 energy recovery systems, operators are able to re-use this thermal energy, for example, to supply hot water in bathroom and kitchen areas or to heat work and office areas, addressing employee sanitation and comfort,” says Atlas Copco Compressor Technique business line manager: oil-free air division JC Lombard. “Reducing a plant’s overall energy consumption will shrink both the electricity bill as well as the CO2 footprint of the utility room, delivering financial and green benefits to the business.”

Lombard explains that this thermal energy is also suitable for process applications: “The hot water can be used as boiler pre-feed or even directly in industrial processes requiring temperatures of between 70 °C and 90 °C, providing a significant saving on costly energy sources such as natural gas and heating oil. This essentially means that operators can scale down or even completely eliminate boilers and other equipment required to generate heat or steam for industrial processes, thereby further adding to the bottom line for business sustainability.”

Available up to 900 kW, the energy recovery systems can be used with the company’s GA oil-injected and water-cooled, oil-free air compressors. These standalone, compact, small-footprint energy recovery units are specially designed for easy installation, operation and maintenance. A dedicated connection kit helps simplify the installation process without affecting the compressor’s serviceability. The systems are available with either stainless steel or copper coolers, depending on the application.

Atlas Copco technicians use an energy saving potential calculator and an assessment of the compressor set-up to indicate how much waste heat can be recovered and the potential savings on a company’s total energy bill.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here