To ensure efficient gathering of relevant data without any risk to human life, international drone services provider Delta Drone Group is using multirotor drones with optical sensors, operated under automatic flight plans, to conduct inspections on cellphone towers.

In 2015, the group signed its first commercial contract with French telecommunications company Orange to assess the best method for data acquisition and processing from cellphone towers. Orange challenged the group to inspect 73 cellphone towers in Europe in 2015 and, satisfied with the services and quality of work that was provided, Orange extended the areas for assessment.

Last year, Delta Drone Group successfully conducted inspections on 144 towers, and this year, the group is responsible for inspecting a further 563 towers in France.

“Orange is active throughout Europe, Africa and the Middle East and, with the success of this contract, we are confident that demand for drones for inspection services will continue to grow,” says the group’s South African subsidiary Rocketmine director Chris Clark.

Rocketmine introduced the use of drones to perform local inspections and survey mining activities in 2015, following the approval of the relevant regulations by the South African Civil Aviation Authority (SACAA). The company, which was the first to operate a commercial unmanned aerial vehicle (UAV) in the local mining industry, specialises in providing survey, mapping and inspection services that focus on enhancing efficiencies and maximising data output on mining operations.

Clark notes that, although South Africa has lagged behind other countries in the uptake of technologies like drones, the market has picked up rapidly in recent years – according to the SACAA’s aircraft register, there are currently 523 registered drones operating in the country, compared with the 195 registered in 2015. He adds that Rocketmine foresees continued growth throughout 2017.

He notes that South African industries were initially sceptical regarding the idea of using technology to capture important data; however, Rocketmine has made it a key strategy to ensure that it not only services clients but also educates them about the technology and its ability to cater to their needs.

“This has enabled us to share our knowledge, ensure that we understand our customers’ pain points more clearly, retain and maintain our long-term relationships with them and drive the use of drones in Africa.”

Automation Enhances Safety, Speed and Accuracy

Clark notes that industry regulations provide specific guidelines on the frequency of inspections for cellphone towers, with elements, such as weld integrity, insulator condition, safety wire status, lighting status and condition, paint and rust condition, structure condition and tower alignment routinely inspected.

Communications towers are continuously exposed to the elements, such as lightening and rain, which are at times severe and capable of causing major damage. The towers should, therefore, also be assessed after severe events to ensure their structural stability, he points out.

In the past, an inspection technician was required to climb up the tower to assess the structure and, thereafter, tasked with consolidating the data needed to perform a structural analysis. Photographs were also taken from the ground and from the tower to provide evidence of damage.

However, Clark highlights that using a drone allows for the immediate elimination of the safety hazards associated with climbing the tower. “Delta Drone’s Delta X – a multirotor drone with optical sensors – can be flown slowly and at very close range to the towers to gather data. The camera is also of a high quality, ensuring better image detail.”

The automated nature of the data-gathering process greatly decreases the time needed to complete the inspection, and enhances the reliability of the data gathered.

Delta Drone designs and manufactures all its own UAV systems, which operate automatically and can carry various sensors, including electro-optical, infrared and multispectral to suit the requirements of the inspection. The multirotor helicopter-type drone has a wingspan of 150 cm and uses a vertical takeoff and landing style. Its unladen weight of 5.8 kg enables it to carry payloads of up to 1.5 kg for speeds of up to 65 km/h.

The addition of thermal sensors is the company’s latest advancement, assisting with thermal imaging for various applications, including electrical inspection, leak detection, pipeline assessments and building efficiency.

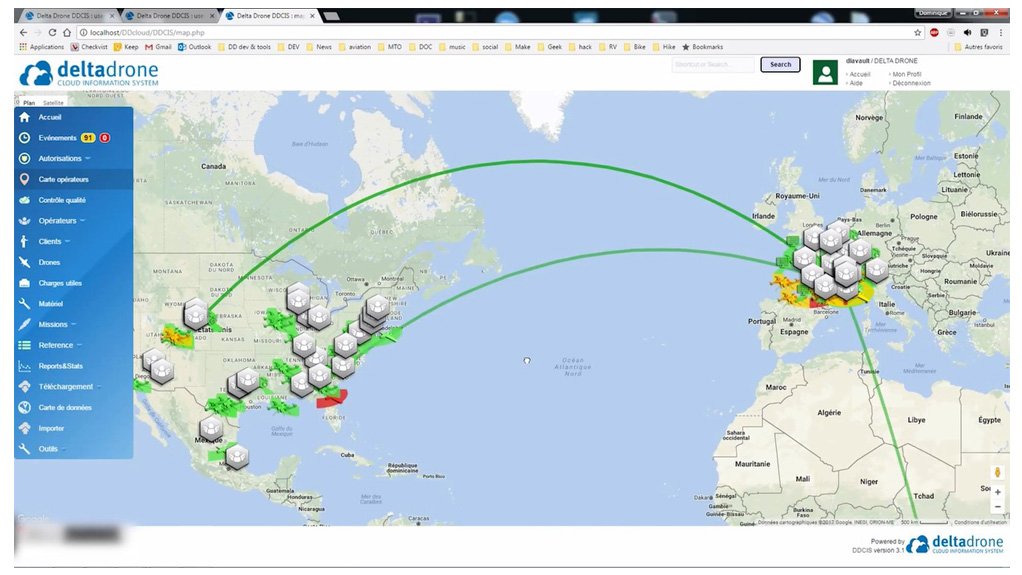

Meanwhile, the Delta Drone Cloud Information System (DDCIS) provides an information cloud that hosts and centralises data gathered from inspections, which is accessible to both internal and external clients. Clark explains that DDCIS is a management tool that provides users with full real-time monitoring, launching and archiving missions. This cloud system allows for data processing and is available to any drone operator wishing to subcontract the post-processing of data.

“The value of DDCIS is that it provides users with data control, historical access, global view and mission tracking, which allows for better decision-making and resource allocation,” concludes Clark.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here