Digital twins can, and should, be used by mine operators as a “testing ground for analysis and scenario planning”, as well as to provide real-time feedback through Internet of Things (IoT) sensors as a means to optimise production, reports Geospatial solutions company 5DGEO principal and professional land surveyor Chris Kirchhoff.

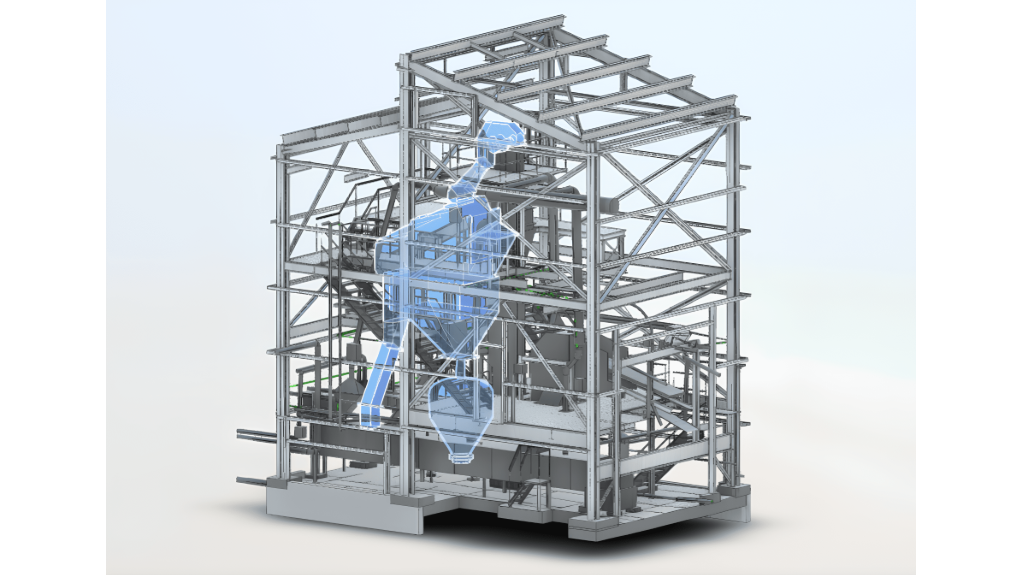

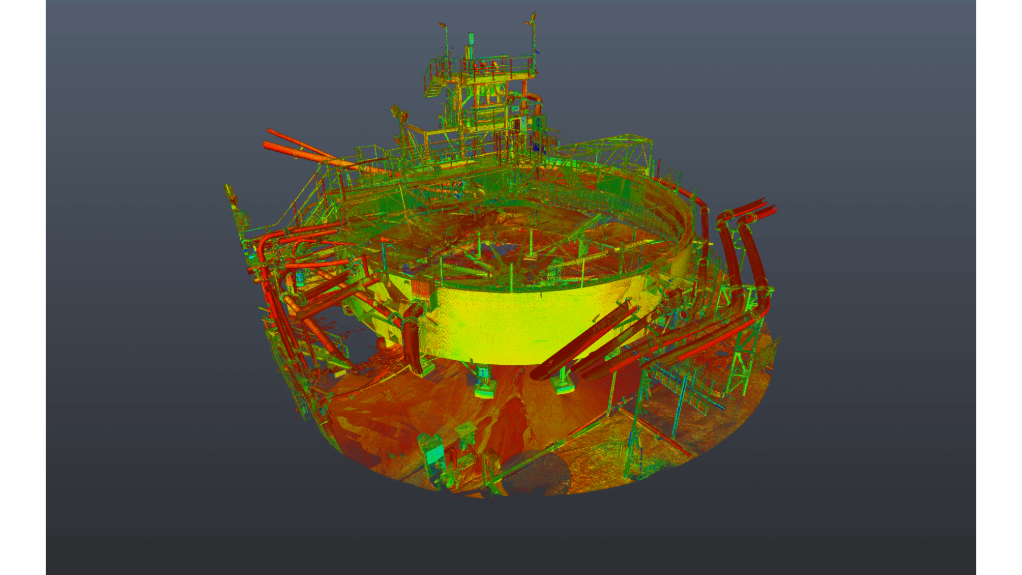

The company equips South African mines with digital twins – a digital profile of the current and historical behaviour of a physical asset and related processes – to streamline mining operations and enhance various processes by using three-dimensional (3D) scanning, drone-mapping and mobile laser-scanning to process real-time, on-site 3D data into information that can be easily interpreted, he says.

Implementing a digital twin for a mine is a matter of equipping such operations with a virtual representation of what is happening at the asset in reality using IoT sensors that report on plant performance.

The IoT sensors that accompany the process of creating a digital twin for a particular mining operation, comes with an array of benefits, he notes.

Firstly, with health and safety being a top priority in the African and global mining industry, a digital twin and its IoT sensors has become important, as it enables mine operators to access a virtual environment in which mine workers can be trained and informed before they enter a mine. This familiarises workers about the intricacies of mine sites and their associated hazards, before entering the physical mining environment.

Further, IoT sensors can assist in identifying which mining operations can be automated, and which should be operated by personnel. This enables mine operators and planners the ability to identify areas where human interaction with systems and machinery can be reduced for the purpose of improving worker safety and improving efficiency.

Data compiled from on-site IoT sensors can also be converted into meaningful and practical information in the digital twin, such as real-time environmental conditions, including the mine-critical factors of air quality, gas levels, humidity and temperature.

“This information allows operators to both identify potential hazards and where hazardous conditions are [originating], and thus, [the ability to] take proactive measures to decrease or remove the risks to the health and safety of staff on site,” says Kirchhoff.

Secondly, a digital twin and IoT sensors can assist mining operations in improving their decision-making processes, enabling the optimisation of operations and improvement in asset management, as well as in reducing operating costs.

Kirchhoff claims that mining operations can use the information provided by the digital twin software to make better decisions, as it enables access to risk calculations, operational costs and helps inform return-on-investment information.

This can equip a mine with knowledge to optimise operations, efficiently manage assets, and use real-time feedback to reduce costs by eliminating operational inefficiencies.

“Improved decision-making, optimising operations and asset management, and reducing costs can be achieved in the areas of enhanced human resource allocation, energy [and] waste reduction, reduced downtime, and an optimised maintenance programme,” he adds.

5DGEO has previously completed several mining operation projects, including improving conveyers and optimising haulage equipment underground for platinum group metals miner Tharisa Minerals’ Tharisa mine, in the Northwest province, and optimising conveyor routing towards ball mills at mining and renewable energy company Exxaro’s Grootgeluk mine, in Limpopo.

The company has also assisted environmental consultancy OMI Solutions with mine plans and registration plans for prospecting right’s applications.

“By having real-time, up to date 3D information of a site from 3D-scanning, drone-mapping or mobile laser scanning, all operations are enhanced because of vastly diminished level guesswork and an improved understating of how circumstances are changing – thus allowing for a proactive approach rather that a reactive approach,” concludes Kirchhoff.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here