- Multotec Manufacturing (0.02 MB)

/ MEDIA STATEMENT / This content is not written by Creamer Media, but is a supplied media statement.

Screening media specialist Multotec is using its ‘deck map’ methodology to constantly raise the bar in optimising screen output and lifespan, according to Shawn Faba, Multotec Manufacturing product manager screening.

“Multotec has built on its concept of the composite deck for over a decade, and differentiated ourselves by developing the deck map to design specific screening solutions for a wide range of material with various characteristics,” says Faba.

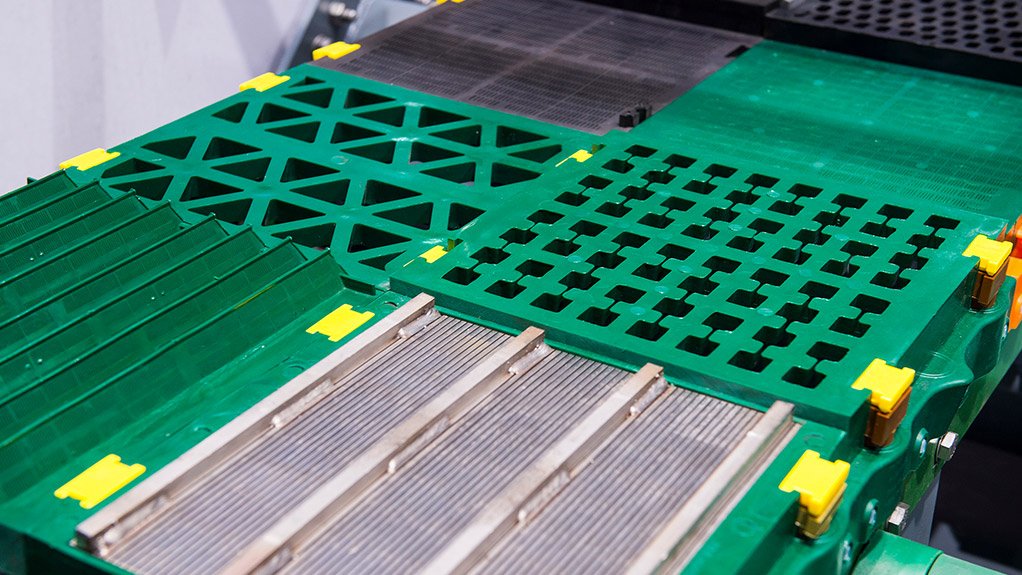

The panels are easily interchangeable on composite screen decks due to the modular format of Multotec’s two common panel sizes – 1’ x 1’ or 2’ x 1’. This modular design allows for different types of panels to be placed in specific areas of the screen as part of the overall goal of achieving metallurgical efficiency on the screening media surface.

With the aim of reducing downtime for customers, composite deck designs must ensure that wear patterns are as even as possible, so that the mean time between failures (MTBF) can be extended and scheduled maintenance can be conducted as infrequently as possible.

“Typically we want to ensure that customers can run these screens for six to eight months at least before they have to schedule maintenance downtime,” says Faba.

The deck map allows the best combination of panels to be placed to suit the conditions, the material and the output targets – employing panel types in materials including rubber, polyurethane, steel, woven-wire, ceramics, Hardox, fibreglass and combinations of these.

For instance, certain applications may demand the use of both ceramics and rubber; while a hard ceramic surface provides resistance to wear and cutting, rubber’s elastic properties dampen the impact forces and protect the ceramic pieces.

“The deck map allows us to specify, for instance, a set of panels comprising highly impact-resistant material at the feed end of the screen, where the impact of material from the feed box or chute is highest,” says Roy Roche, vice president screening media at Multotec.

The performance of the panels is then meticulously fine-tuned through monitoring and iteration, using Multotec’s market-leading Hawkeye technology, which allows management to systematically analyse the data from the deck maps to create a powerful planning system for on-going application improvement. The screening requirements in each part of the deck can be constantly refined by tracking the performance of the various panel types on each deck in operation.

“Modular panels can cut operating costs on screen decks by more than 30% when using iterative improvement techniques,” says Roche.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here