Automation specialist SEW-EURODRIVE has secured an order to supply the latest decentralised drive technology in its Generation C range to automate a new storage and retrieval system being constructed for a US-based vehicle manufacturing plant.

The facility will feed an existing manufacturing facility with vehicle bodies to optimise production and increase its output in response to the growing demand for the manufacturer’s vehicle supply.

“The storage and retrieval system will ensure that the necessary volume of vehicle bodies is supplied to realise production targets,” SEW-EURODRIVE Gqeberha branch manager Phillip Steyn tells Engineering News.

The greenfield project was awarded to Gqeberha-based industrial automation company ROVD, which has worked with SEW-EURODRIVE for 30 years, he explains.

ROVD designs materials handling conveyor systems which are trusted by global automotive manufacturers, as well as by various other industries. The ROVD Group has four subsidiaries, three in South Africa and one in the US.

The order for the US project was placed with SEW-EURODRIVE in March this year.

With SEW-EURODRIVE’s products and services being backed by a global support network and logistical platform, it offers greater flexibility in terms of delivery, notes Steyn.

While some drives will be delivered to the US directly from Germany to streamline shipping and eliminate unnecessary costs, others will be delivered to ROVD in Gqeberha, where drives first need to be installed in South Africa.

“We are delivering drives in phases, as they are required by ROVD, the original-equipment manufacturer. The first order has already been dispatched from Germany, while installation on site is expected to start towards the end of the year and to be finalised around September 2024,” adds Steyn.

The vehicle manufacturer has standardised SEW-EURODRIVE’s drive technology across its manufacturing plants globally.

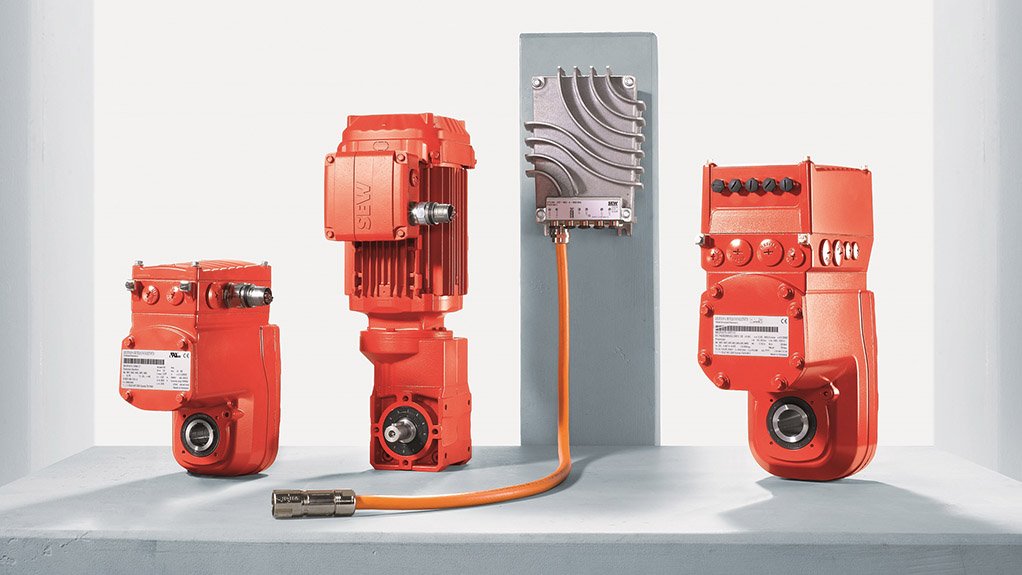

As the pinnacle in drive technology supplied by the company, SEW-EURODRIVE’s Generation C range was specified for the project. Over 300 units of various sizes will be supplied from the company’s latest technology offering, its decentralised portfolio, which enables the drives to be field-mounted and operated independently and in conjunction with each other. Through SEW-EURODRIVE’s decentralised offering, the frequency inverter is either located on or in proximity to the motor in the field.

“These units were calculated to meet the dynamic load demands and rapid cycle times of the automotive industry to ensure that optimal process flow and, ultimately, the most efficient production is achieved. The decentralised drives will be equipped with SEW-EURODRIVE’s digital data interface (DDI) platform. The bulk of the product will comprise servo technology that allows for optimal energy efficiency and, along with DDI control, constant feedback which will result in reliable efficiency and the most effective performance,” states Steyn.

The decentralised technology in the Generation C range and SEW-EURODRIVE’s DDI protocol supports the company’s hybrid one cable technology, which is responsible for power, communication and performance feedback between the drive controller and the SEW-EURODRIVE geared motor.

Decentralised technology focuses on sustainability and consistency across the board, says Steyn when explaining the advantage of employing decentralised drives over centralised technology.

“We have different products within our decentralised portfolio, but they all share the same controller and interface. This interchangeability improves the user-friendliness of the drives as well as aids flexibility as it requires fewer spare parts to be kept in stock.”

Users also benefit from shorter installations and reduced installation costs, as well as faster maintenance turnarounds that reduce production disruptions and productivity losses.

Edited by: Nadine James

Features Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here