Vibrating screens can be designed to suite a range of scalping, sizing, dewatering, drain and rinse, and desliming applications, customised to meet the needs of specific mined products and expected output.

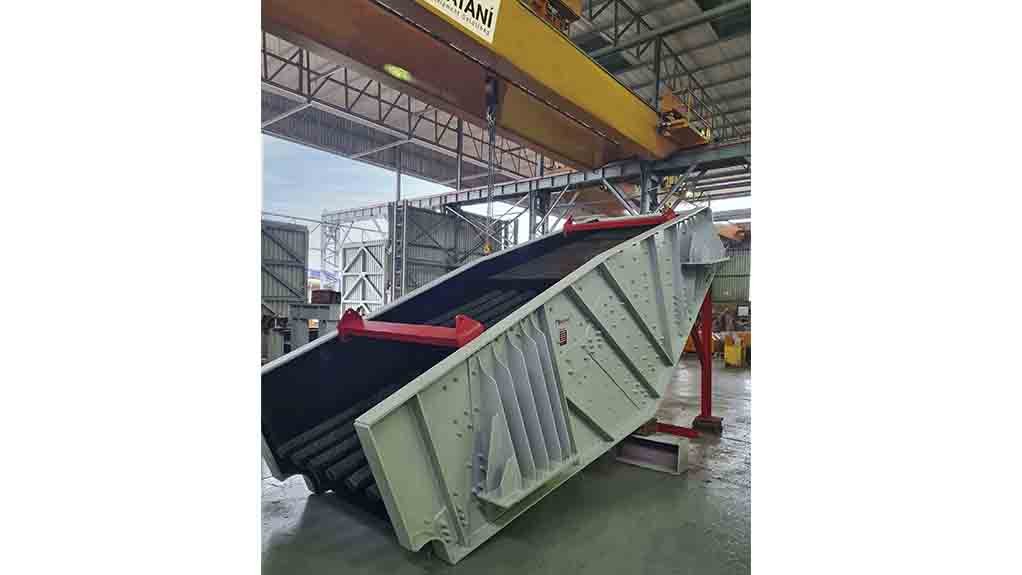

Screens manufacturer Kwatani avers that its success in developing custom vibrating screens is built on experience and practical research. “We focus on the detail of every project, so that the screen performance suits the customer’s mined product and expected output,” says CEO Kim Schoepflin. “This means working with all screen operating parameters like velocity, stroke, angle of stroke and deck inclination – as well as the appropriate screen media – to deliver results.”

The engineering process includes material testing in the company’s laboratory, using wet or dry test screens and other equipment. This allows a differentiated approach to each category of screening required in mining and other sectors.

“Scalping is usually one of the first steps in the comminution process, which subjects screens to intense strain and wear,” she says. “We therefore design our scalping screens for high drop heights, large sizes of material and considerable throughput tonnages, such that they can handle up to 7 000 t of heavy run-of-mine (RoM) material ore per hour.”

This means a very specific design and fabrication of deck beams, traverse beams and side plates, for instance, giving maximum uptime and reliability. Kwatani also designs the scalping panels in-house, aimed at providing the best balance between impact resistance, durability and economy.

The company also supplies custom grizzly feeders for scalping RoM material varying from fine particles to one-metre lump sizes, across heavy duty applications in commodities including gold, manganese and diamonds.

Sizing is a broad category of screening, with wet or dry applications, where mines aim to achieve their required cut-off while maximising process plant efficiency, product quality and production tonnage. For wet applications, the company offers static or dynamic water spray options on single, double or triple deck configurations depending on material, with either unbalanced motors or exciter gearboxes for larger capacity applications.

“To protect screens’ deck components and side plates against wear, our options include a comprehensive selection of rubber, polyurethane and ceramic for greater durability,” says Schoepflin. “The key is to ensure high load capacity, improved wear life and lower operating cost.”

Kwatani’s desliming screens are designed to effectively remove slimes, or fine particles, from larger particles in mineral processing, and Schoepflin says large multi-slope screens are a fashionable choice in this application. She highlights Kwatani’s ability to reduce the transfer of a screen’s dynamic force into the building structure in which it is housed. This is a significant concern in any application, but especially where the infrastructure is aging.

“We design specialised counter frames for each custom screen, to minimise the transmission of forces into the support structure,” she says. “We have a range of screen mounting options – such as rubber buffers and torsional springs – to optimise this isolation effect.”

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here