The South African wing of Germany-headquartered couplings manufacturer Voith has been awarded a contract to provide repair work and spares for a major coal operation in Tete, Mozambique.

Voith regional sales manager for Africa Hans Voshol explains that the contract follows the company’s supply and installation of couplings and complementary products during the miner’s Phase 1 project, completed three years ago, and Phase 2, completed last year.

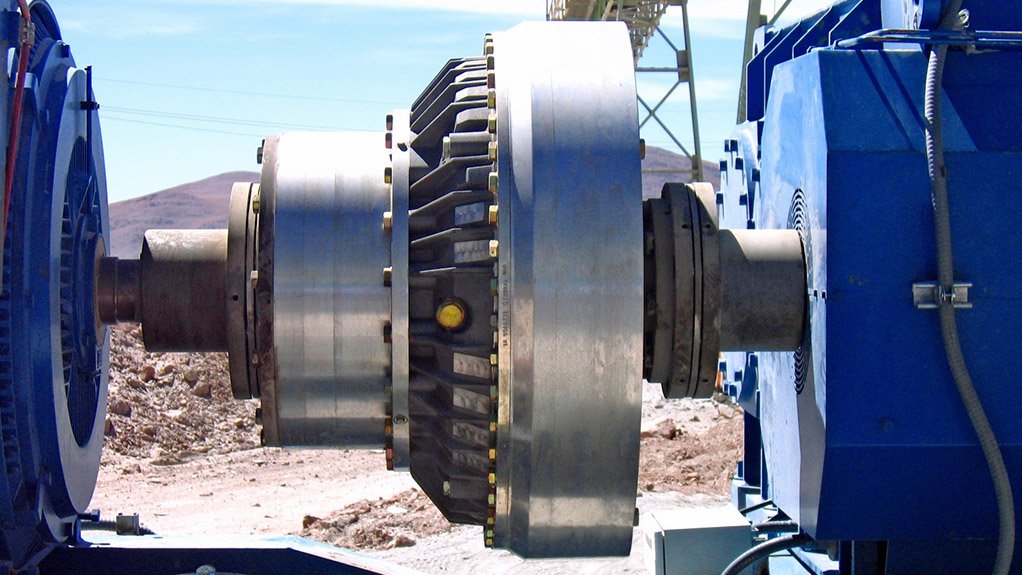

“Voith’s work on Phase 2 of the project entailed supplying 39 Voith fluid couplings, which include the latest fill control technology, as well as all the low speed couplings, at the value of R22-million, for the mine’s conveyor belts. The client requested our products and services, owing to our work on Phase 1,” he adds.

Voith Europe, Middle East and Africa division mining and metals Africa South VP Grant Robinson tells Mining Weekly that the repeat projects are a result of the company’s focus on growing its market reach in Southern Africa.

“Mozambique is an important focus area for us because there is a lot of activity currently taking place in Tete province. Voith was and still is involved in 90% of the current work that is ongoing. We supply the area with drive technology and couplings,” he explains.

“In our extensive work across Africa, we have noted that the biggest challenge to mining is investment; money is short. However, there are several projects that are still ongoing, and we have extensively made our reliable products and services easily accessible throughout Southern Africa,” Voshol notes.

He adds that the company works with local distributors trained by Voith to supply local assistance with technical support from Voith South Africa, stating that in Mozambique the company works with its distributor Encom.

Voshol says, owing to challenges and the low coal price, the installation and commissioning of the Phase 2 project has been delayed and the client has asked for an extension on the warranty of the products that Voith is supplying.

“We agreed to the extension, owing to the known quality of our fluid couplings as long as they are correctly stored and regularly maintained,” he adds.

Meanwhile, Robinson details that the current financial conditions have often led to short-term capital expenditure savings being sought rather than long-term total cost of operation savings that he says outweigh the short-term gains.

He advises that, with Voith’s solutions mostly accounting for only about 0.5% of a project’s overall cost, the best and most reliable products should be purchased from the start to avoid additional spend replacing products after short operational periods.

“We try to show our customers that over the lifetime of their equipment, we are the best value for money option due to higher availability and reliability, combined with ease of operation and maintainability,” he elaborates.

Voshol highlights that the company modifies its products for enhanced operability to suit the client’s specifications from its office, in Boksburg, Johannesburg. Voith has a research and development division in Germany, where it constantly modifies and enhances products to suit industry needs.

Robinson adds that environments where skilled labour is not always readily available, require solutions that can work in harsh conditions, withstand a certain amount of mistreatment, and are relatively simple to operate and maintain.

Voith has a presence in 19 Southern Africa countries, with Zambia, Botswana, Namibia and Mozambique being the company’s most signifi- cant markets, second to South Africa.

Edited by: Leandi Kolver

Creamer Media Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here