Local industrial lithium-ion battery distributor CHASE Technologies GM Brent Frazer explains that the company’s lithium-ion phosphate (LiFePO4) battery packs for forklifts present a more cost-effective, maintenance-free and environment-friendly option for forklift users.

These battery packs provide a reliable power source compared with the older, traditional lead-acid battery option in forklifts used in materials handling for warehouses.

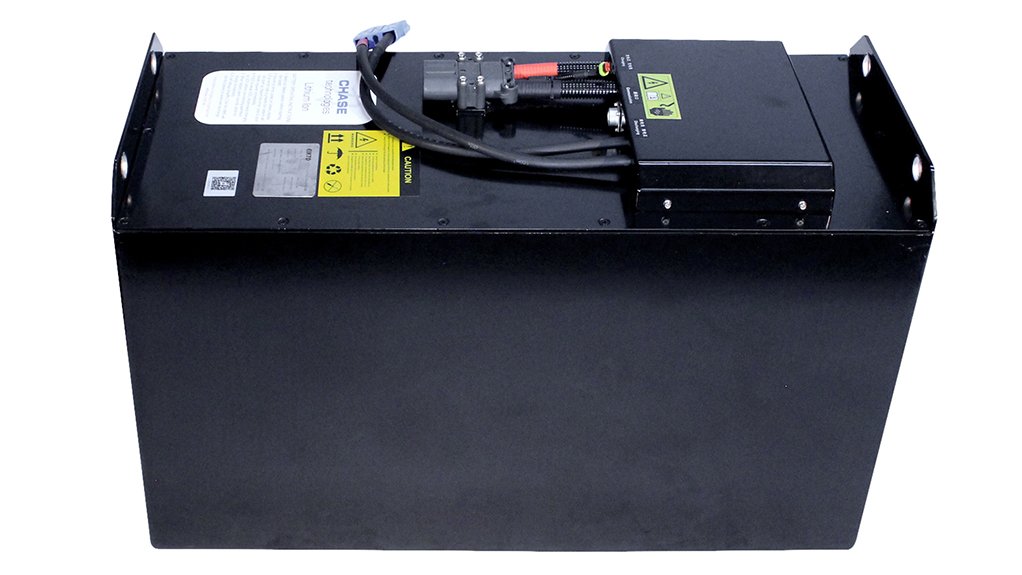

CHASE Technologies currently imports the battery modules and ancillary items, and locally assembles the batteries which are then fitted into forklifts.

The company can configure batteries to fit any brand of forklift.

Frazer particularly emphasises how the LiFePO4 batteries are beneficial for distribution centres and warehouses. The lithium-ion batteries allow for more efficient use of space in a warehouse environment as the LiFePO4 battery packs negate the need for large battery bay areas, normally required for the charging, and swapping out, of lead-acid batteries between shifts.

Lithium-ion batteries can be charged up to 50% capacity within 30 minutes when using CHASE Technologies battery chargers.

The battery packs also include a battery monitoring system, which safely manages the charge and discharge of the battery while ensuring the maximum possible lifespan of the battery.

Frazer highlights that the company has seen an increased demand from customers for the battery packs owing to both the quality and long-term benefit of the LiFePO4 battery system.

Battery Benefits

CHASE Technologies’ goal is to convert 50% of the current local electric forklift market from lead-acid batteries to LiFePO4 batteries within five years.

Frazer explains that a vital step in achieving this goal is educating and informing original-equipment manufacturers and end- users about the benefits of using the CHASE Technologies LiFePO4 system. This becomes particularly important for companies that have been using lead acid battery-powered forklifts for a long period of time.

The LiFePO4 system is the most stable lithium-ion battery as it reduces the chances of thermal runaway – which can occur because of overcharging, internal faults or damage to the battery – making it particularly safe to use in distribution centres and the warehouse environment, Frazer adds.

Further, LiFePO4 batteries do not contain sulphuric acid which is present in lead-acid batteries. Sulphuric acid presents a safety hazard and requires the use of personal protective equipment to handle. The makes LiFePO4 battery packs a much safer option.

While Frazer states that these battery systems might appear to be the more costly option, the longevity guaranteed by the five-year warranty helps to balance out the initial capital outlay and shows financial benefit in the long term.

When the capacity of the battery system is eventually reduced, it can be removed and used for another, lower-power application, Frazer emphasises.

“We’ve been growing constantly, and currently CHASE Technologies has more than 190 battery packs running successfully in the local forklift industry,” he concludes.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here