Advanced engineering solutions provider Fuel Tech received an award for the company’s NOxOUT selective noncatalytic reduction (SNCR) systems for multiple coal-fired utility boilers, with equipment deliveries expected to occur during the second and fourth quarters of this year, as well as the second quarter of 2017.

Fuel Tech’s Selective SNCR systems technology is proving to be a viable solution as combustion unit owners look to comply with more stringent nitrogen oxide control requirements mandated by China’s environmental regulatory policies.

Early last month, Fuel Tech president and CEO Vincent J Arnone announced the receipt of multiple air pollution control (APC) contracts with a value of about $2.2-million from customers in China.

In addition to this, orders were received for multiple Ultra systems that will be installed on units firing coal and municipal solid waste, which are being retrofitted with nitrogen oxide reduction technology.

Fuel Tech’s Ultra process provides for the safe and cost-effective on-site conversion of urea to ammonia for use as a reagent where selective catalytic reduction (SCR) is used to reduce nitrogen oxide. This eliminates the hazards associated with the transport, storage and handling of anhydrous or aqueous ammonia.

Arnone commented that these orders continued to demonstrate the company’s capabilities to provide cost-effective technology solutions for global use. “With our industry-leading suite of APC products and services, we believe we are well positioned to compete for additional opportunities in the domestic and international markets.”

The company’s nitrogen oxide reduction technologies include advanced combustion modification techniques and postcombustion nitrogen oxide control approaches, including NOxOUT, Hert, advanced non-catalytic reduction systems, advanced SCR systems and integrated nitrogen oxide reduction systems, as well as the Ultra process for safe ammonia generation.

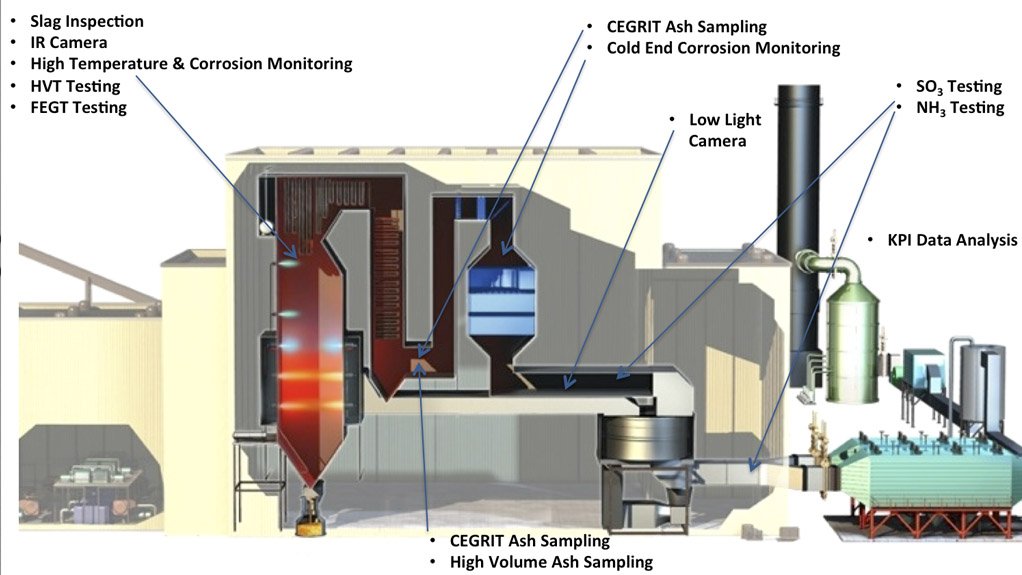

Fuel Tech also provides a range of services, including boiler tuning and SCR optimisation services. In addition, flow corrective devices and physical and computational modelling services are available to optimise flue gas distribution and mixing in both power plant and industrial applications.

Many of Fuel Tech’s products and services rely heavily on the company’s computational fluid dynamics modelling capabilities, which are enhanced by internally developed, high-visualisation software. These capabilities, coupled with the company’s innova-tive technologies and multi-disciplined team approach, enable Fuel Tech to provide practical solutions for some of its customers’ most challenging problems.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here