Unbalances on rotors are the cause of at least half of all faults on machines and systems. With the new SmartBalancer ECO from testing solutions provider Schenck RoTec, service and maintenance technicians can identify these unbalances easily and directly at the location where they occur.

The ergonomic portable measuring device offers great functionality with a distinctive focus on balancing.

The SmartBalancer ECO is the fourth field balancing device released by Schenck RoTec. It is an innovative result of close cooperation between Schenck RoTec India and Schenck RoTec Germany.

The knowledge and experience of decades has been concentrated into the simplicity of the SmartBalancer ECO. The development approach was rooted in the experience that many functions and applications in other field balancing devices are used seldom or never. The SmartBalancer ECO is focused on only three functions, the most crucial, namely overalls, analysis (Fast Fourier transform) and balancing.

Service, maintenance and measuring technicians gain a compact and complete system. It is suitable for preventive maintenance quality assurance and repair, as this portable device proves itself to be a tool that is as reliable as it is diverse.

With the SmartBalancer ECO, the unbalance of rotors in assemblies can be accurately determined and corrected. Without dismantling, all rotor types of any weight class and dimension and speeds of 120 to 30 000 1 /min can be analysed in one or two planes.

Simple Use

The SmartBalancer ECO is as simple as a field balancing device could get – without the burden of making a compromise. Its seven inch touchscreen makes it is as intuitive to use as a modern smartphone. The device is controlled via a virtual control panel in the right of the display.

Symbols and display buttons will be familiar to most users, which makes working with the SmartBalancer ECO really easy. Furthermore, Schenck implemented a balancing procedure that guides the user through balancing steps. Still there is every opportunity to adapt the balancing process to the individual machine situation.

As already known from the “big brother” model, SmartBalancer 3, results are displayed in vector diagrams. If there is the need for a break while balancing, the SmartBalancer ECO offers the possibility to stop the procedure and resume later from the last balancing step.

Results are also easy to read out and can be stored to the structured file manager.

At first sight, the extent of functions of the SmartBalancer ECO might seem reduced. This is intended, as it was Schenck’s approach to develop an economic (which is where the name comes from) field balancing device that sets focus on the most important functions when it comes to machine maintenance.

It covers all truly necessary functions for predictive maintenance and repairs in terms of machine vibration under its blue frame.

In addition to the simplified operating concept, the strengths of the SmartBalancer ECO also includes the personal computer (PC) software ECOSmart. With the aid of this, the measuring results can be transferred directly to the PC and processed as a CSV file and Excel report. Moreover, screenshots from working with the SmartBalancer ECO can be displayed and stored to your computer.

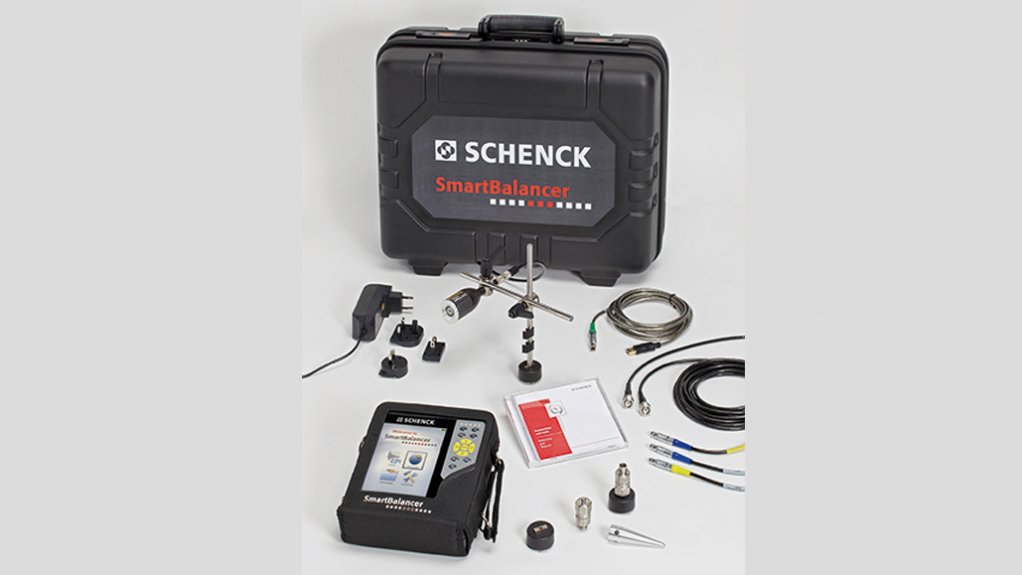

Schenck RoTec offers the new SmartBalancer as a complete solution. The device is therefore ready to use for field balancing in the context of maintenance, servicing and commissioning.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here