A range of mining and industrial product, technology and service solutions were recently featured by SKF at the Mining Indaba 2024, highlighting the company’s drive towards a circular economy and its efforts in assisting customers to achieve economic and environmental sustainability goals.

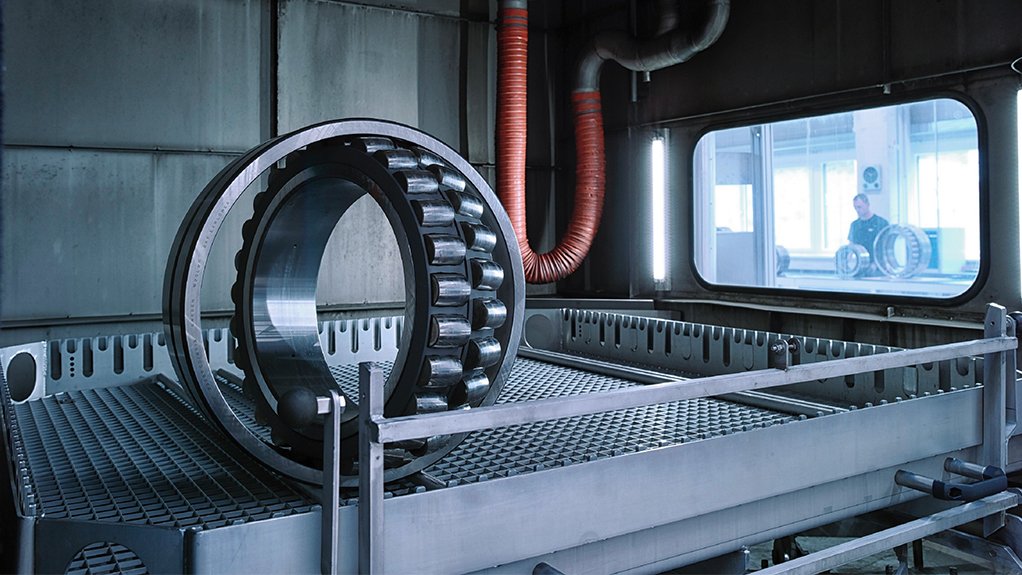

SKF is recognised as a global leader in the development, design and manufacture of premium quality bearings, seals, lubrication systems and related cutting-edge technologies. The company’s capabilities also extend to machine health assessment, or condition monitoring, reliability engineering and remanufacturing.

With businesses doubling down on calibrating increased production with decreased operating costs, coupled with environmental compliancy, the global focus has shifted to creating a circular economy. SKF South Africa industrial distribution and regional sales manager Saien Rugdeo points out that there is a global shift towards creating a circular economy, with a focus on increased production with decreased operating costs, coupled with environmental compliance. Achieving machine reliability and subsequent rotating asset optimisation are pivotal for efficient, sustainable and profitable operation, notes Rugdeo.

Mines face several unique challenges, says Rugdeo, adding: “In a bid to ensure that crucially important factors such as maintenance, repair and operations work, which regrettably do not always enjoy top priority, are prioritised, we must first have a clear understanding of the mine’s vision and ensure that our premium technical support and supply is done through the right channels.”

SKF South Africa says programmes such as Customer Needs Analysis and Stock Inventory Management Optimisation position it to assist mines on the African continent with streamlining supply chains through the procurement of application-specific products.

“Through an integrated approach - product, technology, engineering, reliability, intelligent and service solutions - in collaboration with our wide Authorised Distributor network and our Circular Economy Centre located at our head office in Johannesburg, Gauteng, we have created a strategic, efficient supply chain ecosystem with distributors, customers and end-users,” shares Rugdeo.

The company asserts that training programmes offered to local communities and educational institutions are part of its reliability / circular economy drive. “There is a direct correlation between correct product use and equipment reliability,” stresses Rugdeo. “Consequently it is our objective to train future leaders, engineers and industry pioneers.”

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here