The instrumental job of cleaning an industrial boiler or burner prior to maintenance has proven to be an integral part of rope access company Skyriders’ offerings, says marketing manager Mike Zinn.

“In essence, boiler and burner maintenance is one of our bread and butter jobs.”

He adds that the company services mainly larger chemicals and petrochemicals companies, as well as power utilities, that require constant and consistent safe services.

“Safety is paramount when working on a boiler, owing to the presence of dangerous gases, water and the high temperatures within the boiler having just come off line, as well as the confined space and height challenges that need to be considered.”

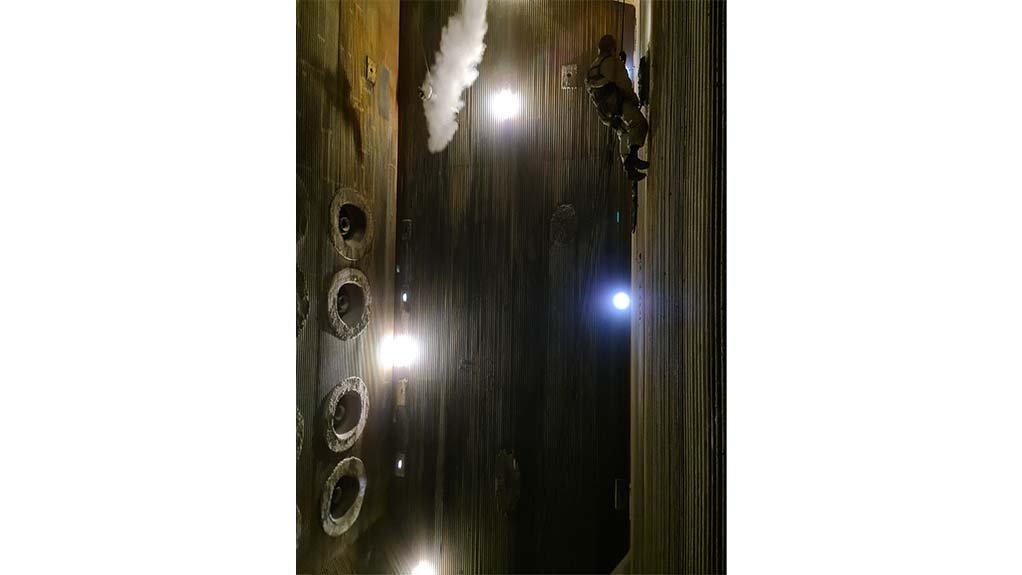

Zinn adds that Skyriders uses an indoor confined-space drone to gather information, and assess the magnitude of the job and any hazards that might be present.

Thereafter, a fully qualified rope access team is dispatched to carry out the initial inspection and cleaning process inside the boiler before maintenance can be carried out.

The service entails the removal of dangerous materials or build-up inside the boiler or burner, known as clinker; consequently making the environment safer for any crew that might need to go into the boiler to repair or replace any parts.

“Unfortunately, the greatest challenge is the unpredictable nature of the work from a schedule perspective – some work is planned but most of the call-outs are a result of unplanned breakdowns, making the scope of the work very time sensitive,” Zinn explains.

He concludes that the company takes pride in getting its team to site, with all the necessary equipment, and having the knowledge to be ready for any boiler or burner situation in a short time.

Edited by: Zandile Mavuso

Creamer Media Senior Deputy Editor: Features

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here