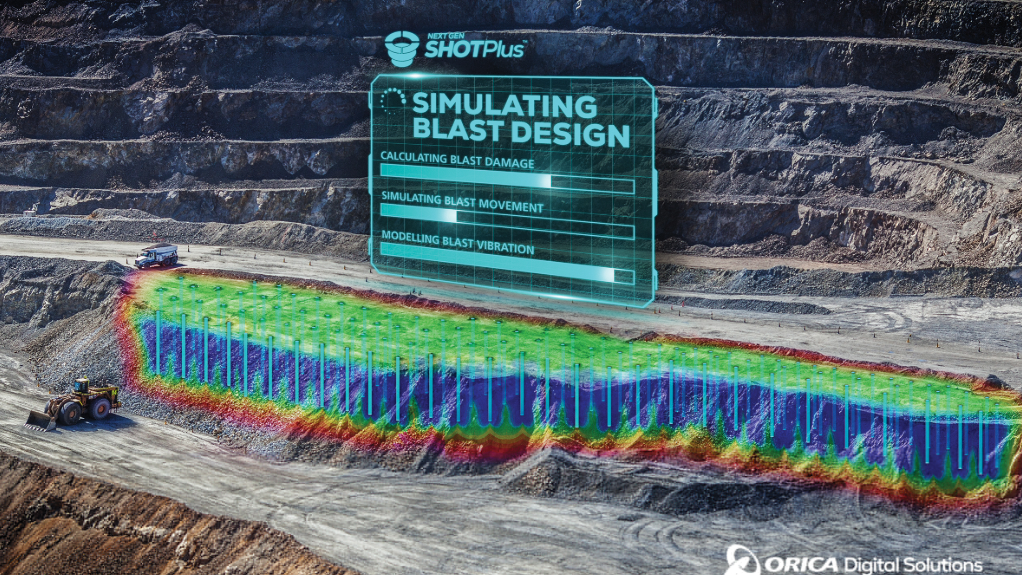

With intelligent blast design and modelling capabilities, explosives and blasting systems manufacturer Orica launched its Next Gen SHOTPlus suite of applications on September 24 at this year’s MINExpo, held in Las Vegas, in the US.

Powered by the Orica Digital Solutions Platform, Next Gen SHOTPlus unlocks the power of the Model Through Time – a cloud-hosted, spatiotemporal, digital replica.

Representing customers’ digital mine through space and time, it provides a dynamic, data-driven replica of their mining operations enabling real-time tracking and storage of spatial data for enhanced and collaborative blast design and modelling. The collaborative nature of the Model Through Time enables in-app design-review capabilities for managing drill and blast approvals within Next Gen SHOTPlus.

Leveraging design tools and predictive modelling capability, Orica Digital Solutions are equipping drill and blast professionals with the tools they need to quantify the impact of engineering decisions on drill and blast outcomes and the associated downstream impacts in near real-time, eliminating guess work from the drill and blast process.

Developed by drill and blast professionals, for drill and blast professionals to effectively improve designs and achieve optimal outcomes, SHOTPlus has been widely used across the mining, quarrying and construction industries.

For 35 years, the SHOTPlus suite of applications has been a leader in intuitive and powerful digital workflows.

“Next Gen SHOTPlus empowers drill and blast engineers to move beyond descriptive drill and blast design so they can design, model and optimise for the best outcome,” says Orica Digital Solutions senior VP Rajkumar Mathiravedu.

He adds that engineers can easily share blast models and predicted outcomes with multiple stakeholders, enabling collaborative assessment of the highest value blast design, in the context of the entire mining value chain.

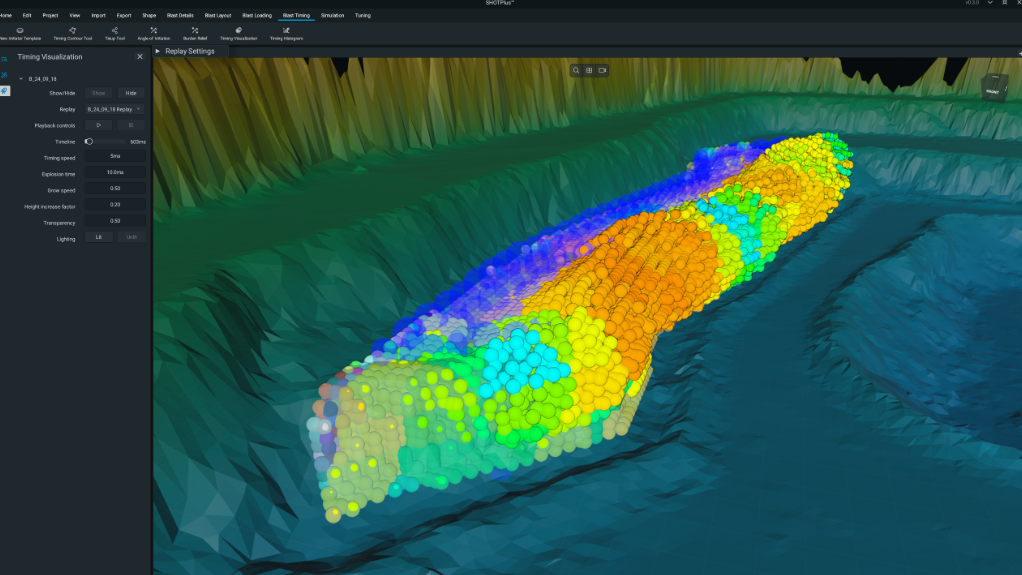

Incorporating Orica Digital Solutions’ proprietary physics engine Helfire Damage Model and Advanced Vibration Management solution, Next Gen SHOTPlus enables drill and blast engineers to model and predict blast movement, damage and vibration.

Predictive blast movement modelling is enabled by Predict Physics Engine, allowing engineers to understand the impact of decisions on the post-blast muckpile.

The Blast Damage feature provides three-dimensional damage modelling, enabling engineers to evaluate the predicted damage generated on both blasted and in-place rock masses.

Blast vibration seamlessly integrates Orica Digital Solutions’ Advanced Vibration Management platform, ensuring users can predict and assess the impact of the environmental constraints of their drill and blast designs.

“Orica Digital Solutions third-party integration enables users who design outside of the Next Gen SHOTPlus ecosystem to benefit from market leading modelling capabilities,” notes Mathiravedu.

Safety, Efficiency, Productivity

Through its development and refinement of its product range, Orica is focusing on addressing the critical need for advanced technologies as mines go deeper and face increasingly challenging conditions.

With its 150 years of experience in mining and civil blasting, Orica reports that its blasting technologies are “transforming” underground mining operations, and enhancing safety, efficiency and productivity across various mining methods.

At the centre of Orica’s underground blasting innovation are three technologies: WebGen 200 Underground Pro, the 4D Bulk Delivery System and Avatel.

Each of these technologies addresses crucial challenges in underground mining, from safety enhancements to operational efficiency and improved ore recovery.

Leading Orica’s initiating systems technology portfolio is the WebGen 200 Underground Pro – a wireless initiating system for underground mining.

This second-generation technology uses low-frequency magnetic signals to initiate blasts, capable of transmitting through rock, air and water.

This innovation is capable of improving safety by eliminating the need for physical connections between detonators, thereby significantly reducing the time workers spend in hazardous environments.

The technology also increases productivity, as its wireless nature enables for more flexible and efficient blasting designs, leading to improved operational workflows.

Orica’s 4D bulk explosives system is capable of loading multiple energy levels in a single blast hole across extended lengths, ensuring optimised energy distribution, resulting in improved rock fragmentation and reduced waste rock dilution, thereby increasing the recovery of finite ore reserves.

This is particularly critical in underground mining, where tunnelling represents one of the most capital-intensive operations.

This innovative bulk delivery system offers flexible energy distribution, as blast designers can easily adjust explosive energy between blast holes and even within individual holes.

It also serves to optimise fragmentation, with precise control over explosive energy leading to improved rock fragmentation.

The 4D bulk explosives system also improves ore management, with enhanced control enabling better management of ore dilution, damage and recovery, compared to conventional bulk explosives.

Avatel

Developed in partnership with mining equipment manufacturer Epiroc, Orica’s Avatel is an automated development charging system, which enables a single operator to prepare and wirelessly charge a development face from the safety of an enclosed cabin.

Avatel combines millisecond electronic timing with WebGen wireless detonators and hole-by-hole bulk explosive energy variation through automated string loading.

This provides a highly accurate and adaptable solution for development and tunnelling blasting operations.

Optimised blast designs and execution using Avatel, reports Orica, can deliver enhanced safety as operator exposure to geotechnical hazards at the development face are reduced, and improved efficiency as labour-intensive and expensive temporary controls to manage risk at the face are removed.

Edited by: Donna Slater

Features Deputy Editor and Chief Photographer

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here