Developing products under proper environmental conditions is being emphasised by mining equipment manufacturer The Baughan Group as providing sustainable commercial solutions to South Africa’s coal mining sector.

The range of products in the company’s portfolio includes various bulk materials handling solutions, such as shuttle cars, feeder breaker machines, scoops and conveyor chains.

The Baughan Group also manufactures railway axles in Germiston, Gauteng, which are supplied to export markets, State-owned port and rail operator Transnet and various mining operations in the country.

The company also aims to take advantage of potential network privatisation efforts by Transnet, which will enable mines and logistics’ providers to become more involved with the use of rolling stock on Transnet lines.

The Baughan Group South Africa MD Derek Anderson highlights that the company concentrates on increasing coal output.

He adds that The Baughan Group is focused on reducing the number of breakdowns impacting customers’ continuous miner machines.

“When a machine breaks down, it has to work extra shifts to make up for that loss, and the mine's carbon footprint increases. All we can do is to help mines reduce their carbon footprint through manufacturing quality products that maximise their output,” notes Anderson.

Collaborative Opportunities, Projects

The Baughan Group’s main projects are aimed at improving products to their optimal capability with regards to the performance that mines intend to achieve.

The company has a sizable mining project in collaboration with voluntary coal mining organisation the Australian Coal Association, whereby The Baughan Group has a well-equipped feeder breaker machine in Queensland, Australia. The company notes this as a productivity enhancing project that will drastically improve the speed of longwall development work.

Anderson highlights the company’s credibility as a key asset in fostering partnerships as this solidifies the The Baughan Group’s position as a key provider of full service original equipment manufacturer (OEM) equipment.

He adds that generally, mine operators want to know that they are getting a good service with the provisioning of quality products.

The Baughan Group also highlights the imperative of ensuring that qualified engineers and metallurgists participate by providing prudent and sustainable commercial perspectives for the coal mining sector, adding that this bodes well for the sector’s investment prospects.

Challenges, New Markets

Anderson laments the logistical challenges that South Africa has been experiencing, but remains hopeful that viable solutions will emanate through collaborative efforts between the public and private sectors.

In highlighting the challenges that this crisis presents to The Baughan Group, he notes that the company has a global network of customers that need to receive their products on time, but that it has had to contend with delays owing to shipments being stuck at, specifically, the Port of Durban, for lengthy periods of time.

Anderson also outlines that The Baughan Group continues to assess future opportunities in developing more products to access new markets.

He explains that the company’s employees have, combined, hundreds of years’ experience at senior level within the coal mining sector, and commends their ability to understand the coal mining market, highlighting that this will guide the company in terms of identifying more opportunities where the company can develop new products.

When The Baughan Group took over the business from engineering equipment manufacturer Dorbyl in 1998, the company’s American partners had already acquired a significant amount of experience in coal mining.

At that time, The Baughan Group employed under 100 people and identified opportunities to grow the business to export markets and implement import substitution strategies to create more employment opportunities, explains Anderson. The group now employs over 400 South Africans.

He highlights that The Baughan Group exports mining related products, which are well established in the US, Mexico, Australia, Indonesia and many other countries. Major axle export markets include the UK, US, Canada, Sweden and the Far East.

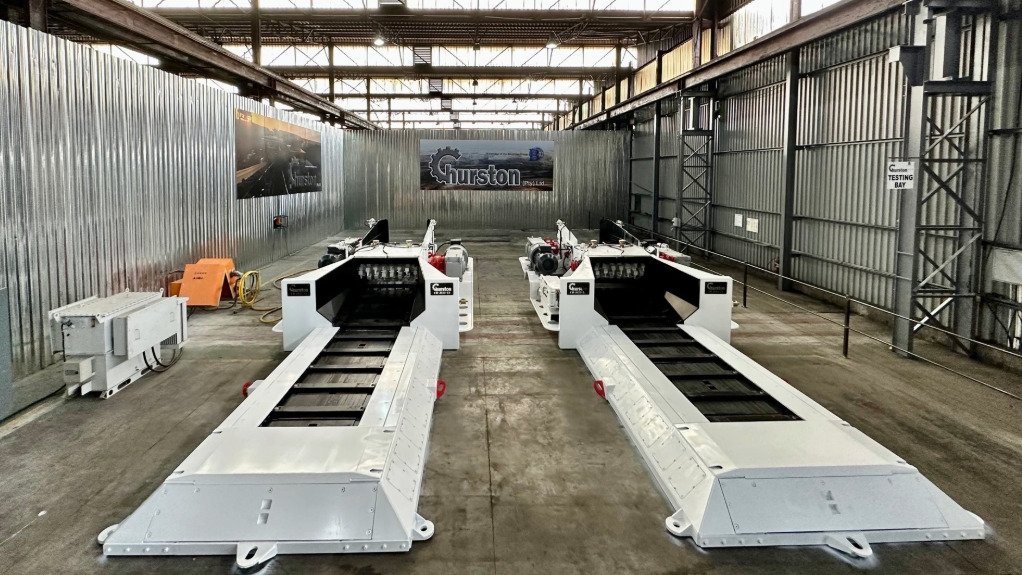

Notably, The Baughan Group has also bolstered its product lineup with additional products available from mining equipment manufacturer Churston and acquired OEM Phillips Global, which manufactures shuttle cars, providing The Baughan Group with a wider range of products for coal mines in South Africa.

The company notes these factors as an opportunity for economic development in South Africa and also asserts that this has contributed to the country in terms of replacing imported products.

“Over time, we will be developing new and better products that will give us an opportunity to outperform our opposition worldwide,” notes Anderson.

Mapping out the future trajectory of The Baughan Group, he outlines that the company will continue to make its contribution to help develop the economy through increasing the scale of the company’s exports and locally manufacturing products, with added focus on manufacturing premium products, to facilitate job creation.

Edited by: Donna Slater

Features Deputy Editor and Chief Photographer

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here