Climate-friendly production solutions that help reduce greenhouse-gas emissions are increasingly being brought into focus as companies aim to decarbonise operations.

To this end, thyssenkrupp Uhde has developed an ammonia production solution based on renewable feedstocks that it says is 100% carbon dioxide- (CO2-) free, designated as green ammonia. In addition to climate considerations, drivers of the move to distributed production of green ammonia from small-scale plants include increased localised self-sufficiency, reduction of transportation costs and import or carbon taxes.

thyssenkrupp Uhde senior sales engineer Nithesh Mohun explains: "Whereas in conventional ammonia plants, ammonia is produced by steam reforming natural gas, thyssenkrupp Uhde’s green ammonia production is underpinned by nucera’s alkaline water electrolysis (AWE) technology. nucera is a sister company to thyssenkrupp Uhde.”

According to Mohun, the feedstocks for the green ammonia production are hydrogen, water and renewable power. Renewable power is produced by either solar photovoltaic, wind, hydropower, or a combination of these sources. He explains that, in green ammonia production, water is converted into green hydrogen by the application of direct electrical current, within the Alkaline Water Electrolysis plant, and nitrogen is produced in an air separation unit.

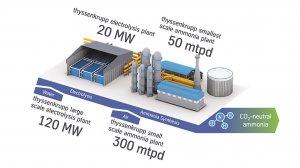

thyssenkrupp Uhde has developed green ammonia production solutions with capacities ranging from 50 t/d up to 3 000 t/d. "Our smaller scale plants in capacity classes 50 t/d, 300 t/d, 600 t/d and 1 200 t/d are offered on a fully modularised basis," adds Mohun. The plants are fabricated, pre-assembled and pre-commissioned as skids for easy transportation. Larger plant capacities are governed by stick-built assembly. The hydrogen and ammonia modular solutions are matched. For example, the 50 t/d module is paired with a 20 MW AWE plant and the 300 t/d module is paired with a 120 MW AWE plant.

The benefits of modularisation include faster implementation, reduced costs, improved quality control, and greater risk mitigation through significant reduction of on-site construction effort and time.

Advantages of small-scale ammonia plants include distributed production location and reduced logistics risks and costs, as it can be designed to service the immediate market, which helps to limit capital outlay and transportation of large consignments of product, as well as reduce the logistics risks of off-loading and storage.

Mohun points out that small-scale green ammonia plants can compete with conventional plants under the right frame conditions. “The key drivers for green ammonia competitiveness are reduced capital expenditure, cost effective renewable power supply and stringent CO2 taxes and penalties. In most parts of the world renewable power is now more affordable than power produced from fossil fuels.

“Governments and environmental organizations are strongly driving enforcement of CO2 taxes and penalties,” continues Mohun. “Considering the above, green ammonia is expected to reach price parity with conventional ammonia production in the foreseeable future, for example by leveraging CO2 incentives and eliminating the need to import ammonia over long distances."

thyssenkrupp Uhde also offers conventional ammonia production plants up to 5 000 t/d, offering the modular A01 and A04 series Gas Heater Reformer (GHR) solution with capacities ranging from 50 t/d to 350 t/d. The GHR solution was developed in collaboration with Johnson Matthey and is based on GHR technology with a pressure swing adsorption system at the front end and thyssenkrupp Uhde low-pressure synthesis loop at the back end.

The design is said to be less complicated than a conventional primary/secondary reformer and is suited for small capacities with low ammonia needs and high transportation challenges. The GHR is designed to be a cost-effective solution as it eliminates the need for an externally fired primary reformer, an elaborate waste heat-recovery section and consequent excess steam production. In addition, the system is designed to operate with air, eliminating the need for an air separation unit. The modular nature of the GHR is also said to reduce implementation time frames, improve quality control and reduce project investment.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here