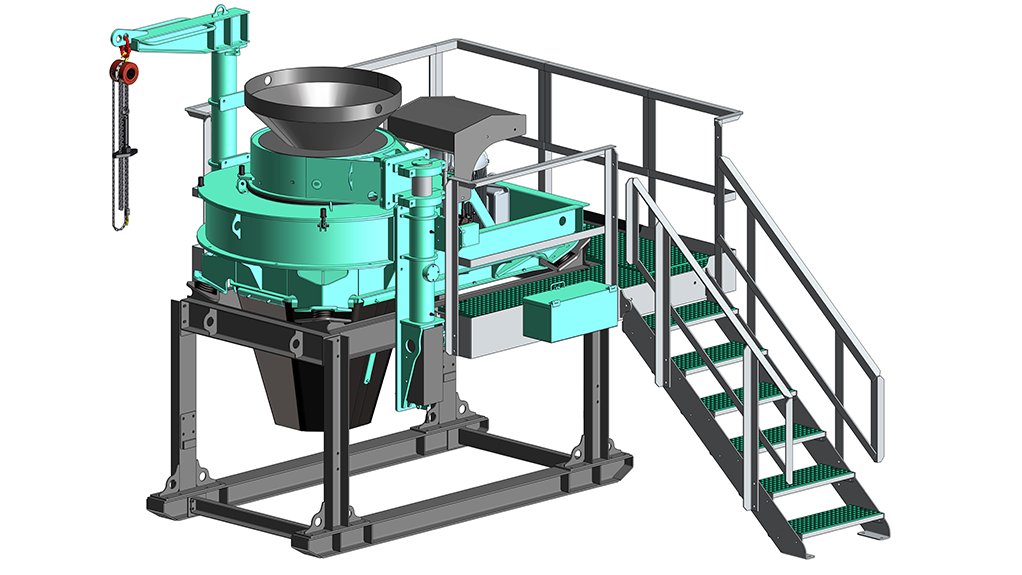

State-of-the-art crushing technology has been used to develop a new vertical shaft impact (VSI) crusher for tertiary and quaternary applications.

The Pilot Modular VS100 is a remodelled and improved version of the entry-level Pilot Modular AC06 VSI crusher, developed using advanced materials and manufacturing methods while retaining the functionality and reliability of the popular AC06 model, explains Pilot Crushtec sales and marketing director Francois Marais. The crusher is used mainly for producing sand and fines and for enhancing the quality of aggregate.

“Among the features of the new VS100 are elements that make for a safer working environment,” says Marais. “These include a new inclined staircase, and a three-sided platform that is both non‑slip and chemical resistant.”

The hydraulic pack opens and automatically rotates the lid, revealing the modular rock chamber and rotor. The jib crane is installed as a standard item, for safe removal of the rotor.

“The modular rock chamber allows you to go from autogenous crushing to an anvil ring crushing configuration, and is designed for efficient rock-box build-up,” he says. “The VS100 is also future-proof – with the option of two rotor sizes, five motor sizes, five rotor speeds and a rotor by-pass system.”

Marais explains that these options allow plant capacity requirements to be optimised with economic power consumption, making the unit versatile enough to allow upgrades as plant production requirements increase.

“Once you start the crusher and the material pours into the newly designed omni-directional feed chute, you notice how smoothly the new advanced vibration isolation keeps the plant running smoothly,” he says.

The new-generation triple bearing, grease lubricated cartridge has an optional Auto Lube system to facilitate regular lubrication for added reliability, while the modular serviceable rotors are designed to reduce operational costs. Once the worn wear parts have been replaced and correct tip material is selected to suit the stone, the rotor can be balanced using the balancing kit provided. Pilot Crushtec SupportLink technicians are available to train maintenance teams during commissioning, to help ensure cost-effective, long-term operation.

“With its improved safety features for overall compliance, this brand new design allows operations to increase tonnages from 10 tph to 100 tph, depending on the application,” says Marais.

He also points to the unit’s ease of maintenance, made possible by the smart design and the simple operations of the crusher. The skid-mounted module requires only a level compact surface for installation and no civils infrastructure.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here