The constant presence of toxic pollutants in the air poses a serious health and environment risk. Humans can inhale particulates with a diameter below 10 μm (known as PM10 and PM2.5), which can lead to severe and chronic respiratory- and cardiovascular-related health problems that can be fatal.

Respirable crystalline silica (RCS) in the form of airborne quartz dust, is commonly found in mining, construction, and mineral-related operations. The effects of prolonged inhalation of RCS can be serious and the monitoring of air quality is an important health and safety function as well as a regulatory requirement.

Occupational exposure limits for RCS vary between countries, although 0.05 mg/m3 per 8-hour shift has now become the maximum in both the US and Australia.

The first step toward complying with these and other air pollution standards, and ensuring safe working conditions for employees, is to undertake regular and accurate monitoring of particulate levels.

X-ray diffraction (XRD) and X-ray fluorescence (XRF) are both non-destructive techniques use for regular and accurate monitoring of particulate levels, to help companies comply with air pollution standards, and ensure safe working conditions for employees.

XRD is the preferred method for the quantification of RCS, as its sensitivity allows for compliance with decreasing RCS exposure limits, and it is designed to handle phase interference in complex mineralogical matrices.

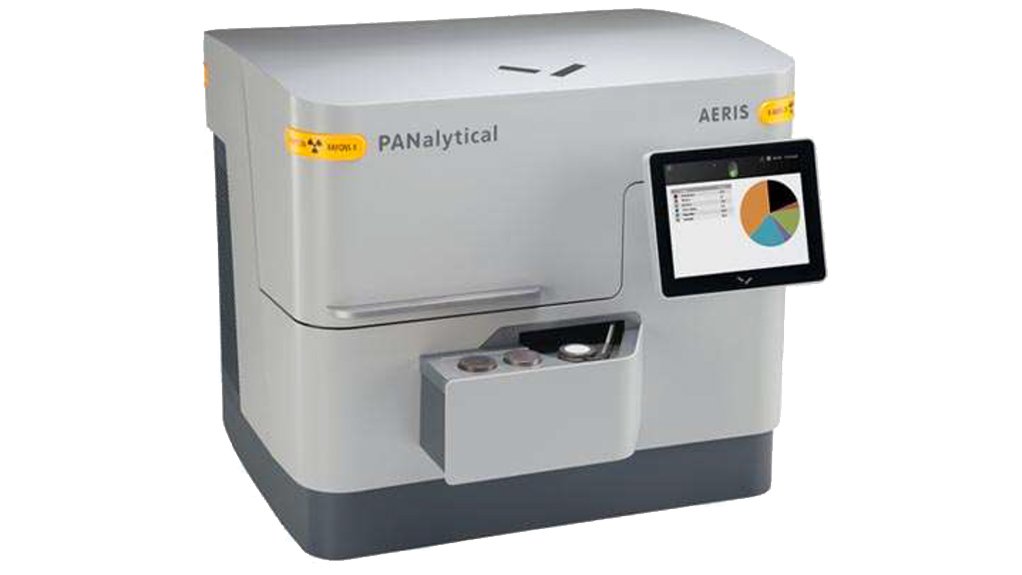

Traditionally, floor-standing XRD instruments have been preferred over compact alternatives. However, there has been a noted improvement in the performance of compact XRD tools, with increased competitive performance and a range of advantages including reduced costs and infrastructure requirements.

Malvern Panalytical highlights a comparison between its floor-standing Empyrean 1.8 kW diffractometer and its benchtop Aeris 600 W diffractometer, where both showed sufficient sensitivity for testing filters in line with RCS regulations, with the benchtop unit offering the additional advantages of a more compact size, simplified optical path and lower operating power.

The company says that its results show that, while its floor-standing unit meets higher throughput requirements as well as serving other X-ray scattering applications, its compact Aeris instrument is a more cost-effective alternative for those seeking XRD with a smaller footprint.

Malvern Panalytical’s Epsilon 4 benchtop XRF instrument is another small-scale solution for elemental analysis of air particulate. In its factory calibration, set up to analyse 46 elements, the tool is compliant with US Environmental Protection Agency (EPA) IO-3.3 regulations, and it can deliver results in 45 minutes for up to 10 samples at a time. In addition, test results show it has a lower limit of detection across the board in comparison to the values reported in the EPA method.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here