Nothing beats a fully cast stainless steel pump for resilience and reliability when faced with a corrosive environment, contaminated water and abrasive solids.

“A protective coating on your standard submersible drainage and sludge pump will only protect your pump until the first scratch,” warns Integrated Pump Technology managing director Colin Adams. “After that, acidity and abrasion can destroy standard pumps in a matter of weeks or even days.”

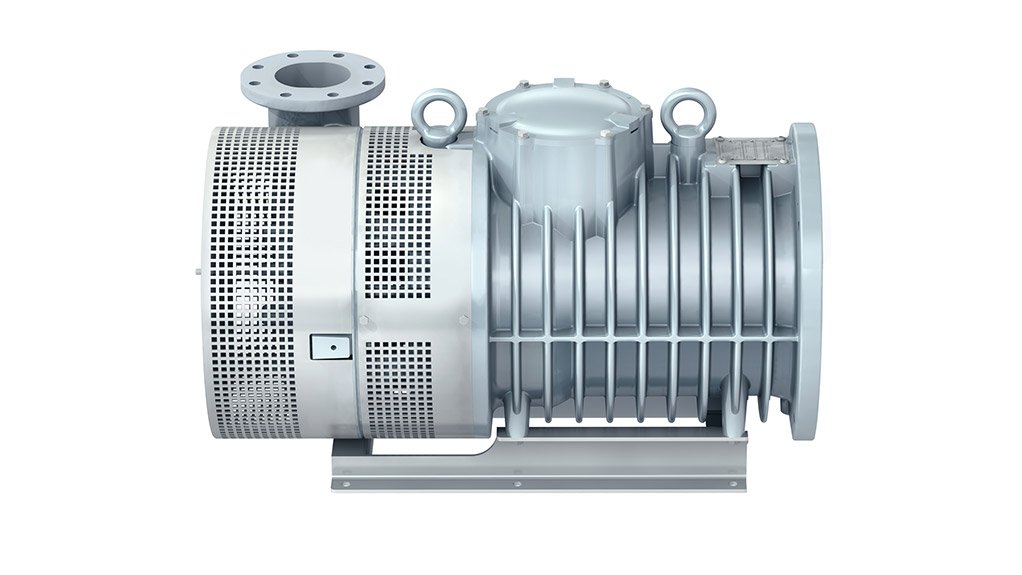

The Grindex INOX series of pumps – distributed in Africa by Integrated Pump Technology – are made of acid-proof stainless steel to operate reliably in pH levels ranging from 2 to 10. This makes them ideal for mines, shipyards, power plants and other worksites that deal with corrosive water, salt water or sludge. All INOX pumps can even be equipped with zinc anodes for extra protection.

The Minette INOX to the Master INOX drainage pumps are designed for pumping water with abrasive particles in suspension, up to the size of the strainer holes.

The Salvador INOX to the Sandy INOX sludge pumps specialise in pumping water with a high content of solids, up to the size of the pump inlet opening diameter. They can pump water with abrasive particles, different types of mud and sludge, or even light slurry.

The Mega Inox – based on the well-proven cast-iron Mega pump platform – is also manufactured completely in stainless steel. The power of this unit makes it ideal for operation in deep excavations where very high head pumping is needed.

Features that make these stainless steel pumps unique include SMART motor protection that prevents damage caused by power failures, an air valve that cools the pump should it run dry, and an outer casing in corrugated stainless steel to handle rough treatment.

The casted acid-proof stainless steel impeller ensures pumping capacities in corrosive fluids, while the diffusers in the drainage pumps are rubber-lined and adjustable to maintain optimum pumping performance. In the sludge pumps, the rubber-lined pump housing is highly abrasive resistant and oil-resistant for longer life. The Grindex INOX model even offers double mechanical shaft seals, with an oil compartment between the seals.

While the INOX stainless steel range is an exciting new innovation in drainage and sludge pump applications, Grindex has been designing and manufacturing electrical submersible pumps for some 50 years. Over 300,000 of these pumps have been supplied in more than 100 countries.