The increasing challenges of dewatering with rising acid levels in mines are being met head-on by associated companies Integrated Pump Technology and Integrated Pump Rental. Cognisance of the need for pumping solutions capable of operating in such highly corrosive environments informs the companies’ product offering of fit-for- purpose pumps and accessories for this application.

Integrated Pump Technology MD Colin Adams tells Mining Weekly that the newly launched 90 kW Grindex Mega submersible stainless steel pump is ideal for these applications in the mining industry.

The pump – the largest in the Grindex range – is available as either an outright purchase or through Integrated Pump Rental as a rental option.

Adams highlights that the Grindex Mega is a fully cast stainless steel pump capable of a 189 m head and flow rate of up to 100 ℓ/s. This pump adds to the existing stainless steel range in the Grindex portfolio and Adams says it is available through Integrated Pump Technology’s strategically placed distributor network in sub-Saharan Africa.

The company also supplies a comprehensive range of electrically driven submersible pumps that can also be used for dewatering on mine sites.

Adams explains that the selection of an appropriate pump will depend on the specific application requirement and his team is able to assess this through interaction with the customer on site visits.

“It is important that a pump constructed from the appropriate material is put to work in a corrosive environment as mild steel and traditional cast iron will not provide the longevity in this sort of high corrosive application,” he says.

Adams highlights that abrasion and corrosion are different and this must be identified and considered during the pump selection.

Integrated Pump Rental MD Lee Vine says that this critical difference is important, and this is why his technical team undertakes full site assessments with customers before recommending the best rental option.

Significantly, it is not always essential to specify a stainless steel pump as sometimes the dewatering application does not require this.

“However, we have largely found that some companies simply send a pump to site without fully understanding the conditions and this is where customers experience what they perceive to be pump failures. These are often as a result of the incorrect pump being specified for a corrosive dewatering application.”

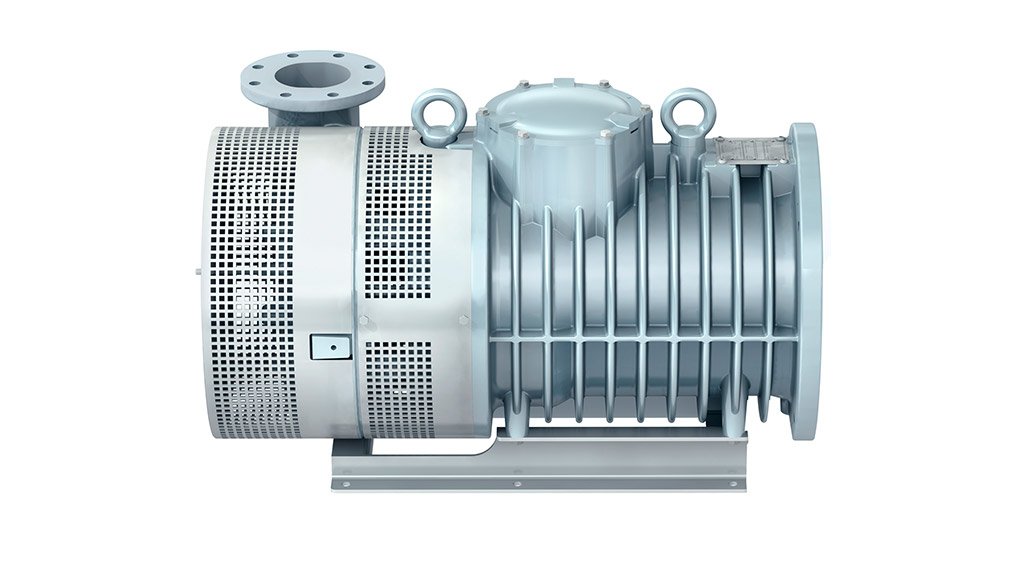

Vine says that as a rental and sales operation his company has closed the gap by offering a comprehensive range of pumping solutions that now includes the new Sykes diesel-driven stainless steel pump.

Sykes pumps are available as either skid or trailer-mounted units enabling them to be deployed easily to sites. The range offers units, depending on the application, that can pump up to a 200 m head and flow rates of up to 400 ℓ/s.

Moreover, the proven Faggiolati stainless steel pump has been in increasing demand in instances where a submersible pump solution is required and where the pH level is extremely low. The design of this pump with integral fully cast stainless steel components ensures optimum reliability in acid mine water drainage applications. The pumps are available for either outright purchase or rental.

Also available are pumping accessories, which include pump flotation devices, as well as hose flotation devices. These are manufactured from high-performance polyethylene with stainless steel mounting components facilitating long life in challenging pumping conditions.