- Artificial intelligence (0.04 MB)

/ MEDIA STATEMENT / This content is not written by Creamer Media, but is a supplied media statement.

Artificial intelligence (AI) may not be a new field of technology, but it has recently gained traction. Thanks to rapidly increasing computational power and the rise of Big Data, there are more business cases for smart technologies emerging every day.

While we’re not yet cruising around in self driving cars, one area of AI that is attracting attention is machine learning, where algorithms are being developed that “learn” continually and therefore meet goals faster and more successfully.

AI and machine learning are already playing a role in our lives, from the product recommendations we receive online and content that arrives in our social media newsfeeds, to the fraud protection we receive behind-the-scenes when we use our credit cards. More companies in the packaging and labelling industry are asking how these smart technologies can benefit their businesses, both now and in the future.

Unlock value from your data

Today’s product owners and packaging companies have access to more data than ever before – in their sales and marketing departments, on their lines, and in the back office. Now, smart technologies are available that can collect, clean, structure and analyse these vast data sets in order to find valuable insights on customer behaviour, performance trends, quality issues and more amidst all the data “noise”. In this way, AI and machine learning technologies can provide accurate intelligence and predictive insights into production that can guide better business decisions and boost profitability.

Boost operational efficiency

In many companies, information technology systems aren’t integrated, which makes it difficult for colleagues to share data, collaborate on projects and optimise productivity. Smart technologies can help to bridge these divides, automating manual processes and creating more seamless workflows across the entire supply chain.

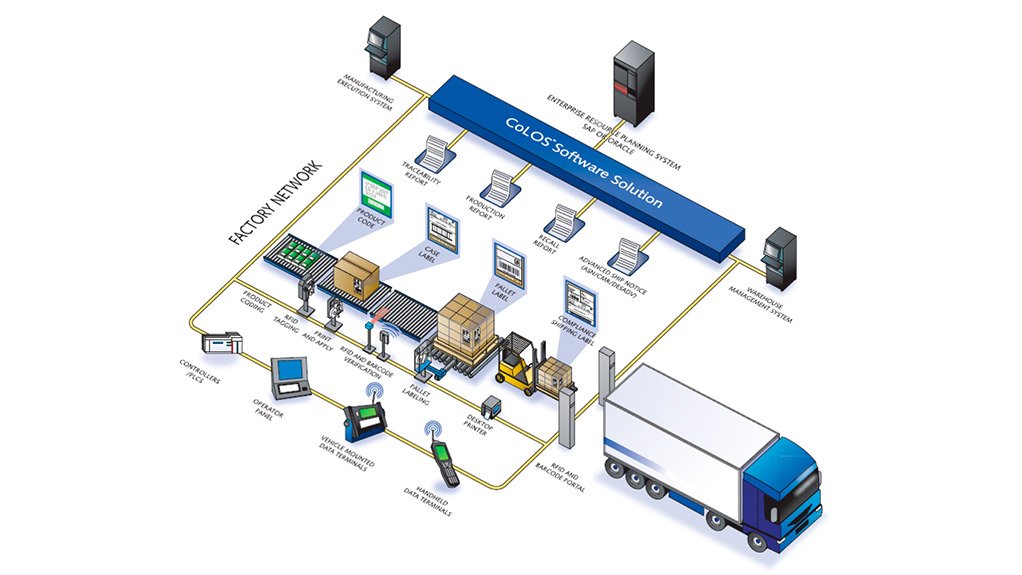

For example, you could also opt for an easy-to-use, scalable and customisable software like Markem- Imaje’s CoLOS® from Pyrotec PackMark, which allows you to integrate equipment networks along your production line into a smarter, more streamlined, centrally-managed system.

Enhancing predictive maintenance

Predictive maintenance takes data from a wide range of sources (such as sensor data collected from all the equipment on your lines) and uses machine learning techniques to anticipate equipment failure before it happens. Instead of just monitoring data, smart technologies can put insights into action – reacting much faster to potential failures and breakdowns than traditional continual monitoring techniques.

For more trends, tips and advice on anything related to labelling, coding and print & apply labelling technology, contact Pyrotec PackMark.

Edited by: Creamer Media Reporter

EMAIL THIS ARTICLE SAVE THIS ARTICLE

ARTICLE ENQUIRY

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here