SKF is supporting the growth of the aerospace market and its business by investing in a new automated line located at the SKF Aeroengine site in Valenciennes, France. With this investment, SKF is strengthening its flexibility and competitiveness in France.

In January 2019 SKF inaugurated a fully automated production line dedicated to the production of SAFRAN's LEAP engine components. This strategic investment is part of the Group's modernisation of its production in France. It also contributes to strengthening SKF's expertise in rotating equipment performance and improving the level of customer service around the bearing.

SKF is investing in a new digital manufacturing line in order to optimise its production capacity and support major customers in accelerating production volumes by end of 2020. "This growth is impacting the aerospace market. Consequently, reacting to the changing market situation, SKF is adapting its production capacity," explains Philippe Peroz, Aerospace Business Unit Manager.

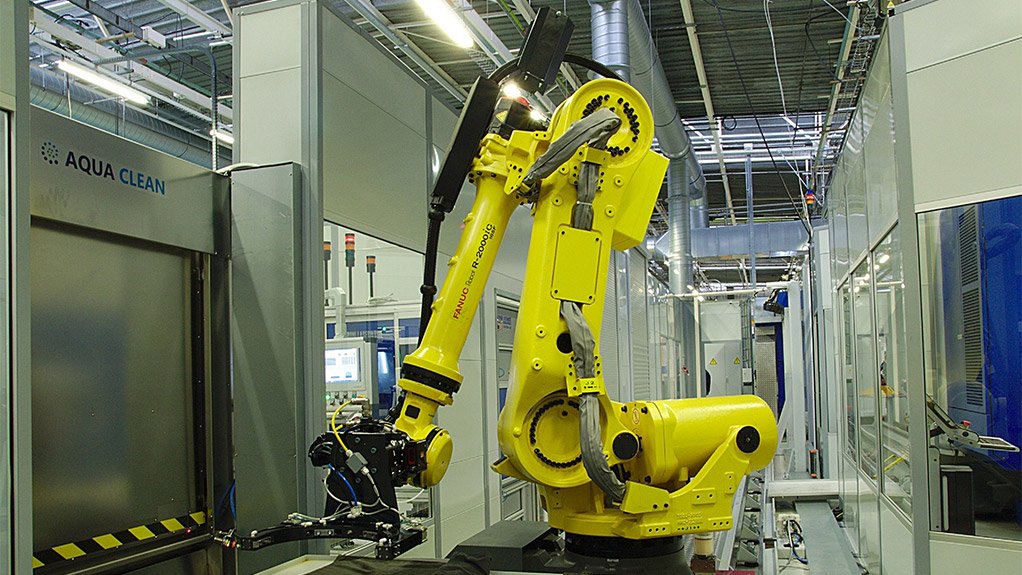

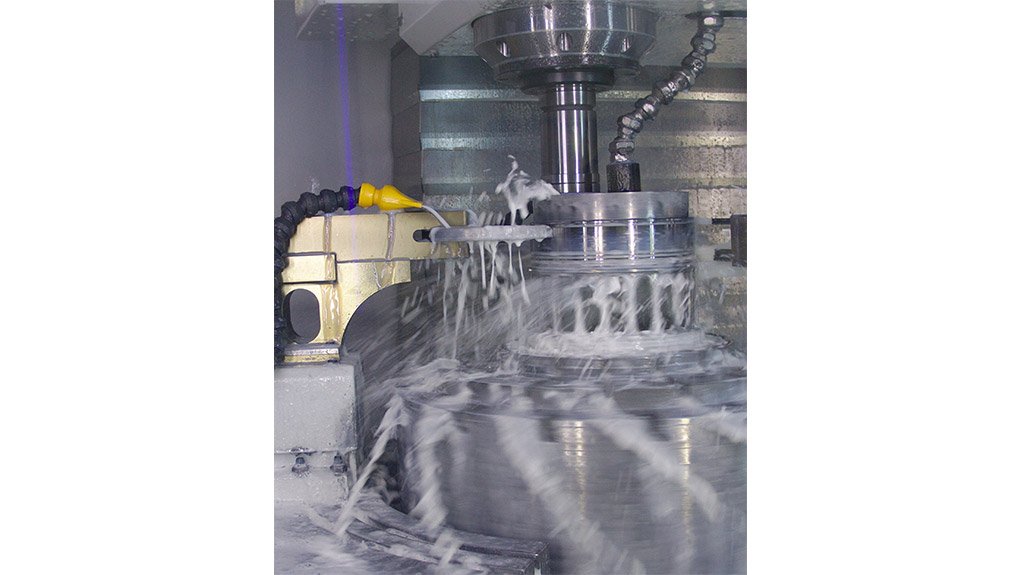

The investments include turning and milling machinery, and the installation of an automated assembly line with a robot allowing the fully-automatic operation of the line.

It is the first line of the SKF Aeroengine France plant, which integrates four key stages of the production cycle dedicated to engine components: turning, milling and grinding, control and traceability.

With 550 employees, the Valenciennes site is producing engine and gearbox bearings for market leaders, both for the domestic and international market. It is listed as center of excellence for the SKF Group in aeronautical bearings.