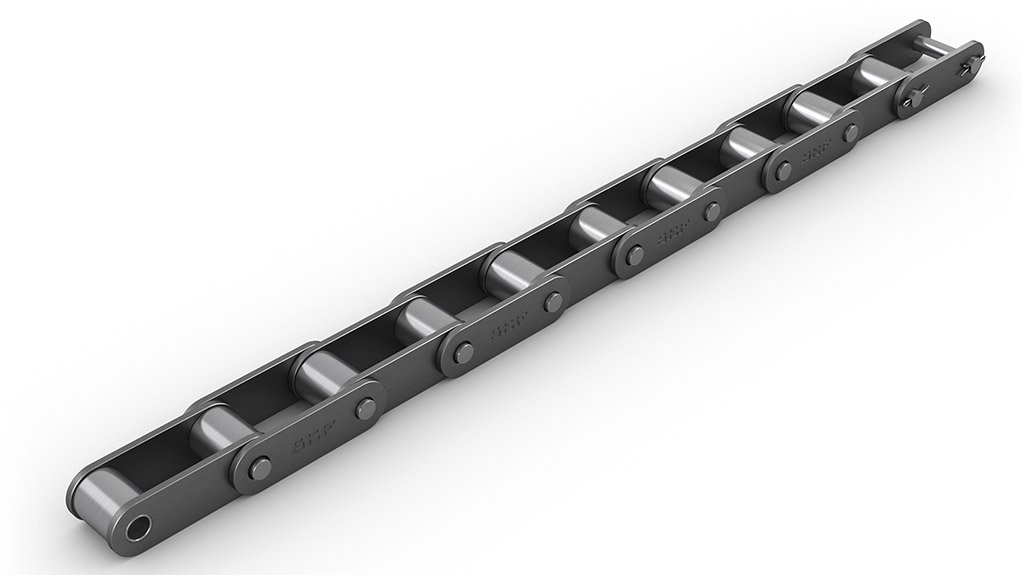

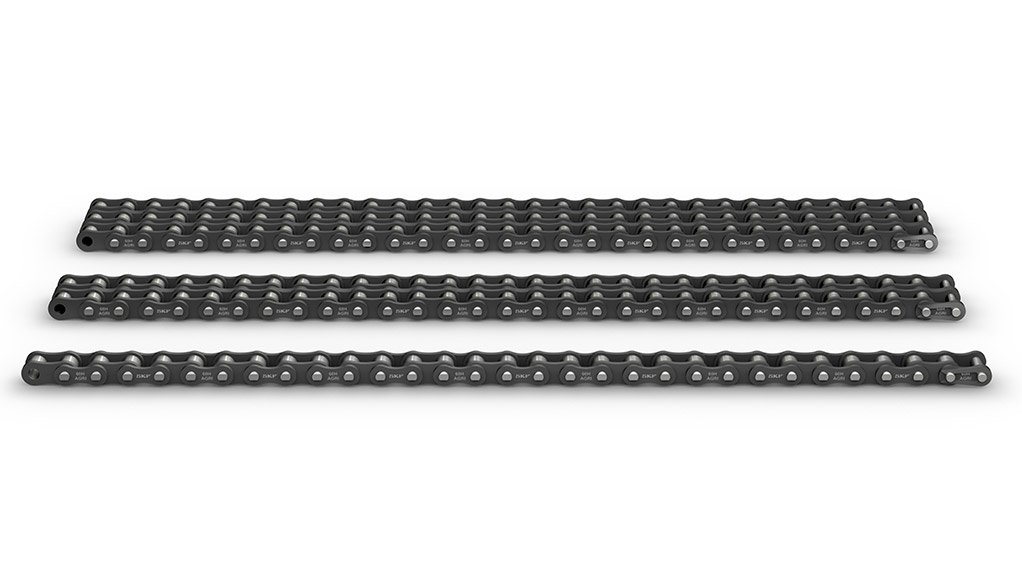

SKF agricultural roller chains as well as special combine, baler and drive chains, are used extensively in the agricultural industry on a range of machines and equipment that includes combine harvesters and headers, planters, feed mixers, balers, etc.

For a farming business to be sustainable, farmers need high quality, rugged components built to last and to perform optimally in tough conditions. Farm equipment is exposed to extremely challenging conditions. At the start of the season, equipment is put through intense work after a long period of inactivity. Throughout the full crop cycle, from soil preparation and planting to irrigation and harvesting, farmers expect their equipment to perform optimally in dusty, muddy, wet, rocky soil conditions paired with extreme heat and cold.

“Farmers simply cannot tolerate breakdowns in the field resulting in extremely costly unplanned downtime to allow for repairs,” states Charl Engelbrecht, SKF Key Accounts Manager - Agriculture. “In addition to losses in productivity, equipment failure can also negatively affect yields. Power transmission is the vital link between moving parts. A chain failure on critical equipment can result in extended downtime and lead to further breakages. Expenses can be measured in time i.e. downtime and unproductivity as well as money i.e. the cost of replacement parts.”

To ensure high machine and equipment performance, efficiency and reliability throughout the season, Engelbrecht recommends a two-pronged approach: “Annual inspection of equipment so that parts can be replaced, if required, before the equipment goes out into the field. Secondly, equipment must be fitted with durable and quality components specially designed to withstand demanding work conditions.”

SKF develops and designs agricultural chains in close collaboration with equipment manufacturers, distributors and end-users. “As a result, our chains are able to meet stringent demands and address farmers’ real-life needs. Owing to our customer-focussed approach, SKF agricultural chain works when and how it is supposed to and is interchangeable with industry standard OEM chains,” states Engelbrecht. “For optimum chain performance, we also highly recommend using the right lubrication systems and products such as SKF battery driven grease guns, single point lubricators, and medium and high temperature chain oil.”

SKF, together with its brands PEER, Chicago Rawhide and Lincoln, provides a broad solutions portfolio for the agricultural industry with products suitable for equipment in all stages of the crop cycle. SKF’s range of bearings, lubrication solutions, cassette seals, etc. have been specifically developed to help meet the growing demands of the dynamic agricultural industry. Irrespective of the type of farming equipment – from complex combine harvesters to specialised attachments - SKF’s comprehensive product offering delivers high reliability at low operating and ownership costs.