The war between Russia and the Ukraine has impacted the local food and beverage sector on several fronts, says bearings and power transmission supplier Bearings International (BI) market segment developer and fast-moving consumer goods leader Hennie van Vuuren.

The war has made the rand volatile, which has hampered consistent pricing in the industry, causing the company to review their prices more frequently, he adds.

It has also increased costing in the sector, owing to heightened fuel prices, which have, consequently, affected shipping costs. A global shipping backlog, a consequence of Covid-19, has been exacerbated by the war, therefore impacting on local importers in the sector.

Van Vuuren explains that, despite the impacts of the war, the company’s stock planning system and in-house warehouse facilities have enabled BI to keep its prices relatively consistent.

“The downside of this, however, is that we can sometimes overstock when demand is not as high as anticipated, but we try our best to be consistent in our offering,” he adds.

New Offering

BI introduced field services as an additional value-added service delivery mechanism for clients last year.

This service enables the company to assist clients with installations, condition monitoring, alignment, maintenance, reverse engineering and refurbishment.

Van Vuuren says refurbishing machines enable clients to save costs.

The company also provides industry-specific business development leaders to advise clients when there is a change in the market in terms of products and offerings. The leaders also provide up-to-date information on specific industries, as well as on products available internationally.

“We would like to believe that we are ‘head of innovation’ in the industry. We have a specific approach to the food and beverage industry to deliver high-quality products and related services,” he notes.

Industry Innovations

Van Vuuren says players in the bearings industry, including BI, have embraced technological enhancements for its products and that the market identifies easier with existing technologies used for new applications.

Since 2020, the company has been embarking on awareness campaigns to ensure that clients understand the benefits of these enhancements.

These benefits include more reliable and longer-running applications, thus ensuring less maintenance and downtime for plants.

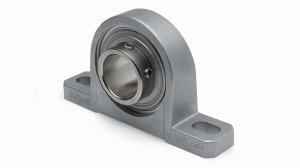

While thermoplastic housings, sealed for life, maintenance free stainless steel and, to a lesser extent, ceramic-bearing applications, are not new to the market, they are now sought after by the food and beverage industry.

These innovations ensure that bearings can endure in high-heat, -moisture and submerged environments, while the products can be used in difficult-to-reach areas and critical operational applications.

Further, because equipment used in the food and beverage industry has to be washed regularly, high water pressure and high temperatures can negatively impact on bearings and their seals. Bearings supplied by BI can withstand harsh conditions and, consequently, prolong equipment life.

Van Vuuren says the company has received positive feedback on the results of the bearings supplied for the industry, whereby its thermoplastic offerings have proven successful in withstanding harsh conditions; these offerings are also more hygienic, easier to clean and last longer.

“We have created awareness of the benefits and customers are now getting more reliability and longevity out of their plants because of the uptake of the better products that we can offer,” adds Van Vuuren.

BI supplies a wide range of bearings and associated engineering products to the food and beverage industry to meet customer requirements on all levels.

The company supplies its products to industry players, including original-equipment manufacturers, raw-product producers and materials handling customers, as well as to all machines used in the food and beverage industry.

These machines are used for processing, production, bottling, canning, packaging, extraction, malt, feeds, fisheries and meat.

“The BI culture of ‘always there, making it work’ puts us in a position to deliver quality and value to all our clients. BI has a rigorous and stringent supplier and product selection process, which includes technical support from our trusted suppliers and to ensure that all suppliers live up to the high standards as required by our clients.

“With BI’s specific market segment approach, we can focus on delivering tailor- made solutions to clients and not just off-the-shelve replacements that have not kept up with trends and technology,” Van Vuuren concludes.