Local ultralow-profile mining machinery and equipment supplier CMTI Consulting’s MT100 ultralow-profile mining machine has successfully operated for more than 500 hours at several gold and platinum mines throughout South Africa, CMTI Consulting MD Dr Danie Burger tells Mining Weekly.

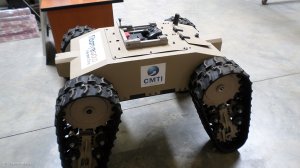

The MT100, with a sweeper and a dozer attached, is a battery-driven platform with a maximum height of 420 mm and a battery life of seven hours.

The company is currently in the preproduction phase of the development of the MT100 and the MT1000. The MT1000 underground mining machine is equipped with a drill rig and mechanical breaker for nonexplosive mining or a multidrill rig, which can drill four holes simultaneously for conventional blasting.

The first fully developed MT100 and MT1000 machines will soon be delivered to gold miner Sibanye Gold’s Burnstone gold mine, in Balfour, Mpumalanga.

CMTI Consulting, Sibanye and hydropower specialist Hydro Power Equipment are converting part of the mine to ensure the machines can be used there. Burger says this includes general rehabilitation and establishing an underground workshop, as well as installing optical fibre in the workspace and two hydropower units to drive the machine drills and piping.

He notes that Burnstone’s panels are currently mined at a height of 1.5 m. However, using the machines will result in their being mined at 1 m, which will enable the mine to extract significantly more gold-bearing ore and reduce waste-rock extraction, thereby increasing yields and reducing waste-disposal costs.

Burger says the company is on course to introduce both machines for full commercial use at Burnstone by mid-February or the beginning of March.

“The MT1000, powered by means of a trailing cable with the patented multidrill attachment, can drill four holes simultaneously. The principle behind this is that the holes can be drilled as quickly and as accurately as possible at the right angles. This enables a 30 m panel to be drilled in just one hour, while it currently takes five rock-drill operators between five and six hours to do the same amount of work,” he explains.

Burger contends that it is, therefore, now possible for three rock faces to be worked in a single shift, instead of only one.

The battery-driven MT100’s multi- purpose platform can also be equipped with a laser scanner, supplied by mining software company Maptek, which is mounted on top of the platform. The machine can be sent into dangerous areas without endangering the operator, as the person operates it from a gulley up to 100 m away, Burger says.

The sweeper and dozer attachments allow for the remining of previously mined, but difficult-to-reach, areas, where there could still be some reserves in the form of fines.

“There are significant reserves that could not be mined previously; however, with the application of our ultralow-profile mining machinery, the extraction of millions of dollars of valuable mineral resources is now possible,” Burger enthuses.

Its ability to enter narrow reefs that were virtually impossible for people to enter before also allows for the MT100 to be used for mine mapping.

Although both machines are based on a multitrack concept where four tracks are individually driven, they can also swing around a centre point, enabling the machine to negate vertical obstacles as high as 400 mm, he adds.

Burger tells Mining Weekly that CMTI Consulting is working on developing a new type of 10 t underground hybrid diesel-electric locomotive.

The locomotive features include self-steering bogeys with regenera- tive breaks, alternative current permanent magnet motors (developed by CMTI Consulting), a fully enclosed cab and triple-laminated windscreen, as well as infrared -assisted cameras with video displays, which have been strategically placed throughout the locomotive.

It is a fully front-driven unit, with extra-heavy-duty batteries and underground railway control systems manufacturer Battery Electric’s pedestrian detection system, and the locomotive can be remotely operated.

The first version of the locomotive, which was completely electrically powered, was successfully trialled for the past 18 months at 4 Shaft of Sibanye’s Kloof gold mine, 60 km west of Johannesburg.

However, the company is converting the locomotive into a hybrid model and is scheduled to complete the project by the end of March. The locomotive will then be returned to 4 Shaft for further trialling.

Edited by: Martin Zhuwakinyu

Creamer Media Senior Deputy Editor

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here