Power transmission products distributor Bearings International (BI) has earmarked KwaZulu-Natal as a key growth area for its business going forward.

The company’s Durban branch stocks a range of bearings, electric motors, gearboxes, lubricants, seals, tools and power transmission products for several industries.

The branch is managed by Trevor Veeradu, whose engineering expertise has stood him in good stead with regard to industrial gearboxes and conveying systems, specialising in light and heavy duty rubber belting and, thereafter, in hydraulics and pneumatics.

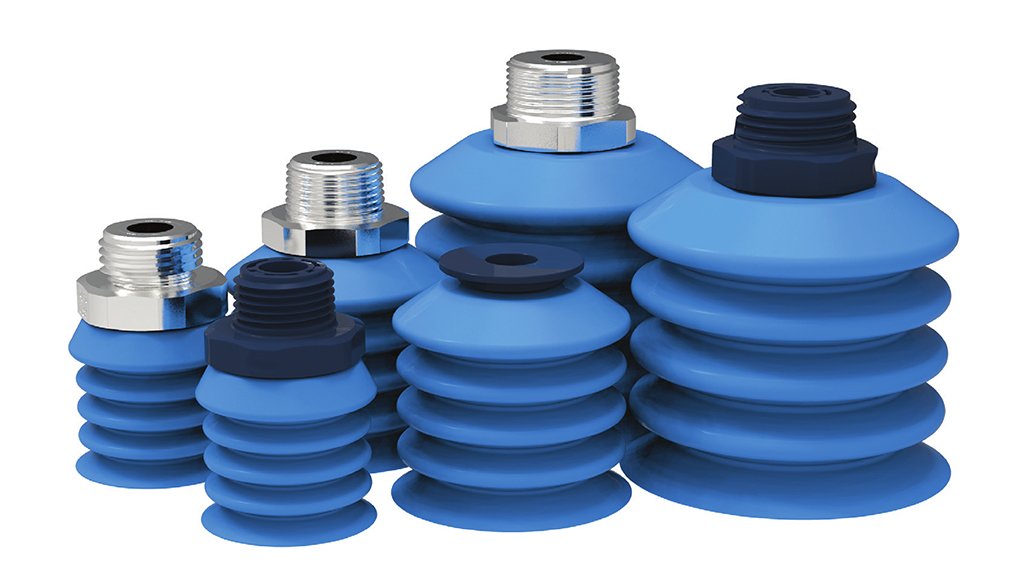

BI has been at the forefront of pneumatic component and specialist process automation supplier Berntel’s pneumatic and hydraulic solutions in recent years.

Berntel is expanding its footprint by offering its extensive range of pneumatic products through the BI branch network. This, in turn, expands BI’s value proposition to its customer base by offering complete solutions for different market segments.

Acquired in 2014 as a complementary company to pneumatic and hydraulic automation solutions provider Ernest Lowe, Berntel expands engineering firm Hudaco Group’s – which BI is also part of – industrial offering in pneumatic, hydraulic, vacuum, process and automation solutions.

Berntel not only manufactures its own pneumatic cylinders but also designs, builds and commissions control systems, including programmable logic controllers.

Berntel will introduce its latest agency, Italian designer and manufacturer Ober. The company, specialising in portable pneumatic tools, motors, automated machinery, as well as systems for drilling, tapping, threading and screwing, including power screwdrivers with electronic torque control, has been active in the pneumatics market globally since 1952.

Further, BI Durban offers support to the province and also supplies customised solutions for large-scale technical projects in various sectors.

These include mining, petrochemicals, food and beverage, cement and quarry, pulp and paper, port and rail, water and sanitation, as well as sugar mills and animal-feed plants.

The branch has an in-house division that refurbishes sugar mill carrier and diffuser chains, and assembles and supplies new chains. BI Durban also manufactures specialised sprockets as per customer requirements.

Other services include bearing inspections and fitments, condition monitoring, gearbox repairs, technical advice for all projects, bearing reconditioning, vibration analysis, specialist manufacture, on-site operations, troubleshooting and 24/7 service.

The BI Durban staff are kept up to date through ongoing training, which is also offered to customers upon request.

Veeradu comments that the company’s strength lies in its people and knowledge, and BI’s commitment to servicing customers who have supported the company over the past 65 years.

“We have great plans to extend our product offering even further in the future and, as part of the Hudaco Group, our value proposition to customers is commensurately larger.”