Pumping solutions provider Integrated Pump Technology is addressing the dewatering challenges in mining operations by providing specialised pump solutions designed for water-logged and remote mines.

The company’s strategy revolves around maintaining a strong distribution network and ensuring the availability of its dewatering pumps to meet the urgent requirements of mining clients, says Integrated Pump Technology MD Jordan Marsh.

A key challenge that Integrated Pump Technology faces is ensuring that its pumps are accessible in remote areas: “Accessibility is a key factor for us.”

Quick response times, as well as having well-positioned distributors near the mines, with sufficient stock of pumps, are crucial, as Integrated Pump Technology can then deploy its dewatering pumps quickly when required.

Water management is a top priority in mining and delays can lead to operational setbacks.

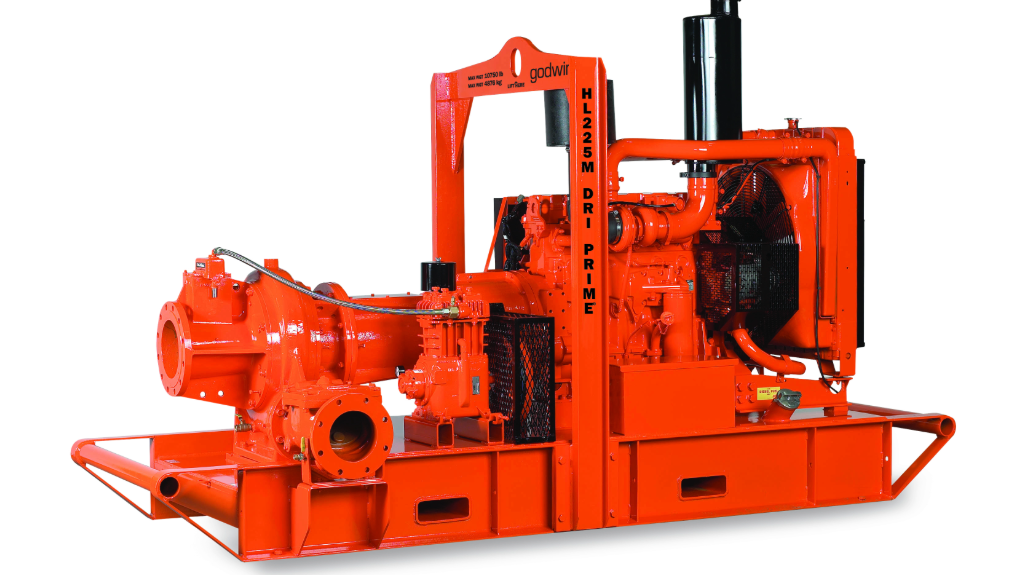

Integrated Pump Technology’s dewatering solutions include Grindex submersible pumps and Godwin self-priming pumps, which offer various features aimed at improving efficiency and reliability.

While the market “is full of” competitive products, Integrated Pump Technology focuses on providing pumps equipped with advanced technology.

“Our dewatering pumps include smart systems that enable them to run automatically and protect the pump during operation.”

This automated functionality is designed to ensure continuous operation without requiring manual intervention, which is particularly useful in challenging environments, he adds.

In addition, Integrated Pump Technology’s pumps come equipped with air valves that enable them to run dry when necessary, and stainless-steel options are available for increased durability.

Marsh highlights the versatility of the pumps, which can handle dewatering, slurry and sludge requirements across various applications.

Stock Availability

A critical factor in Integrated Pump Technology’s strategy is ensuring that the right equipment is available when needed.

“Stock is king,” Marsh emphasises, adding that the company has focused on carrying sufficient stock in areas where its products are in high demand, particularly fast-moving items.

Maintaining stock availability helps Integrated Pump Technology meet the immediate needs of mining operations and reduces operational delays.

Integrated Pump Technology also provides service support in countries such as Zambia, the Democratic Republic of Congo, Mozambique and Botswana.

These centres are staffed with personnel who can offer on-the-ground support and maintenance: “It’s important for us to have service backup and people who can be on site at the mines,” Marsh explains to Engineering News.

Integrated Pump Technology’s sales and service teams work closely with distributors, regularly visiting mining sites to ensure a unified approach which, consequently, enhances customer support.

Further, Marsh stresses the importance of providing aftermarket support: “It’s easy to sell pumps, but if there’s no aftermarket service, it becomes a challenge.”

The company has developed a service offering to provide peace of mind for clients, as it knows that its pumps will be supported throughout their operational life.

This commitment to service includes regular maintenance, ensuring that pumps continue to operate efficiently and reliably. Marsh says the company’s investment in service infrastructure enables Integrated Pump Technology to stand by its products and ensure that clients can rely on long-term support.

Stock availability, the distribution network and a robust service offering are therefore key components in contributing to Integrated Pump Technology’s performance in the mining industry.

“We are only as good as the people we work with,” Marsh adds, emphasising the importance of reliable distributors and service personnel.