The use of counterfeit bearings has become increasingly prevalent in the local bearings industry, which can increase downtime, create consequential damage and reduce life span and safety, says bearings and power transmission supplier Bearings International (BI) product manager Andrew Altree.

“Counterfeits are not covered by any warranty offered by the brand owner. This negatively impacts on service contracts as anticipated, as the life expectancy will not be achieved, resulting in continuous downtime and associated costs. In addition, there are severe negative health and safety implications in all applications when using counterfeit bearings.”

BI’s products are imported and the company has faced challenges of late, including the global supply chain disruption caused by the Covid-19 pandemic, which resulted in ports being closed in China, with no vessel or container availability, as well as the war between Russia and Ukraine.

Despite these challenges, BI MD Bart Schoevaerts enthuses that the company achieved “significant growth.”

He explains that BI’s expansion into Africa has been sustained, owing to heightened demand.

“It is just a matter of how we approach that market. We do not want to grow too quickly, as sustainable growth should give us a solid foundation. I am positive, however, and believe that we will continue to go from strength to strength.”

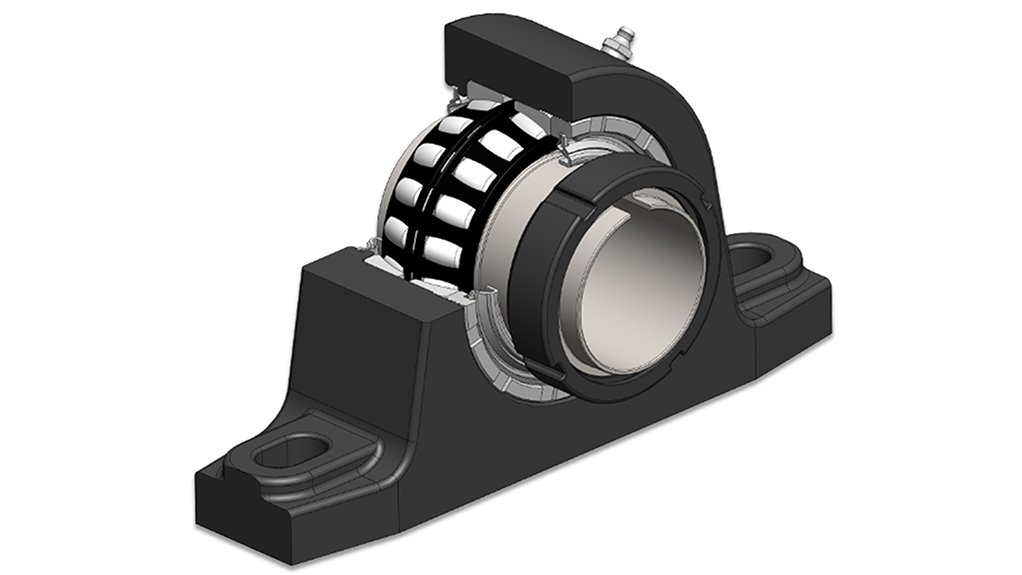

BI launched the Rexnord RN Series of metric bearings and Cross Ocean Company (COC) Series bearings at the end of last year.

The RN series of metric bearings can carry higher loads and acts as a drop-in replacement for existing SN500 bearings, consequently increasing efficiency and productivity while reducing downtime and total cost of ownership.

The series has a misalignment capability of two degrees, a two-piece outer race, and higher radial and axial load capability, owing to a larger roller design and seals for improved bearing life, ease of fitment and removal from the shaft owing to a Shurlok mounting.

Further, BI became the exclusive distributor of all COC products in South Africa and sub-Saharan Africa in September.

The main product lines are unitised spherical roller bearing units for all industrial applications, and a world-class, fully stainless steel range of ball bearing units for the food and beverage industry.

BI is expecting to launch new brass cage copper bearing units next year.

Further, the company expanded its national distribution range by opening four branches this year and aims to add a new complementary business unit as it celebrated its sixty-fifth anniversary last month.

Schoevaerts concludes that the market has moved away from the traditional concept of technical support to one where customers keep abreast of the latest technological developments.