By Thomas Schatz, SMS group GmbH, Moenchengladbach, Germany,

More than half of the produced copper products are cast and rolled wire rods. It is used as the semi-finished product for electric conductors, which are present in virtually all equipment and functions reliant on electricity in our daily lives.

Copper is the primary metal driving electrification and is essential for energy transition plans worldwide. The new approach to electrical energy generation is characterized by a more diversified and distributed power generation compared to traditional power plants. Consequently, technical solutions now demand a significantly higher quantity of electrical conductors. For example, the generation of wind energy requires four times more of electrical conductors than nuclear or coal power plants. In fact, the demand for copper conductors in a single wind generator is approximately 30 tonnes!

At the same time, there is an intension to shift the mobility concept from combustion engine vehicles to electric vehicles, further driving the demand for copper. In addition to the vehicles themselves, the charging infrastructure requires extensive use of copper conductors.

Numerous countries have announced their ambitions decarbonization goals for the next decade, making the sourcing of sustainable green energy a key priority in the challenge against the global warming. Looking ahead, the outlook indicates that copper demand will grow from the current 25 million metric tonnes per year to about 50 million metric tonnes per year by the year 2035.

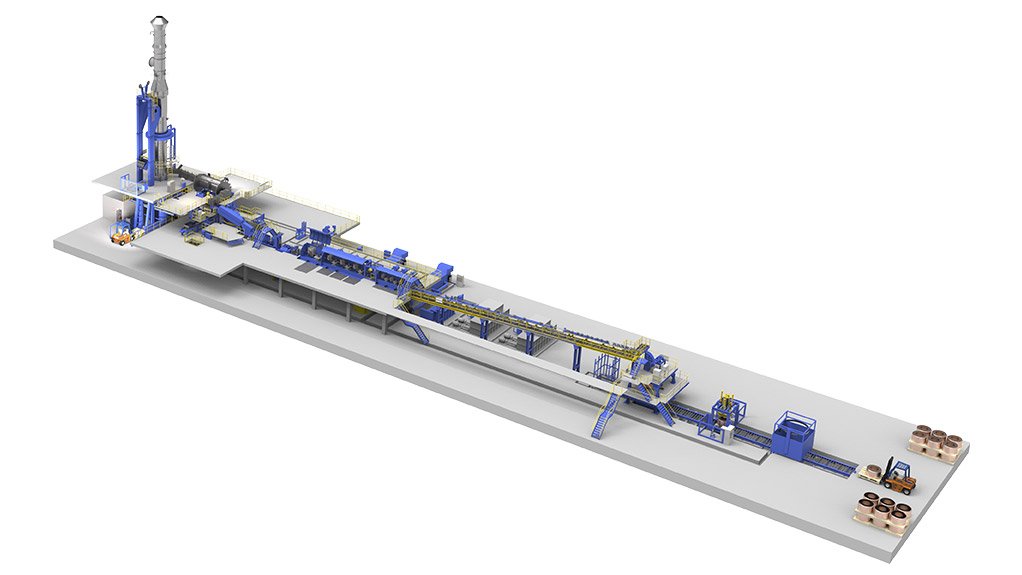

CONTIROD®: Powering Copper Conductor Production

The combined process CONTIROD®*, a cutting-edge technology for production of semi-finished electric conductors is ready to support the energy sourcing transformation. SMS group draws from 50 years of experience in copper wire rod technology. Our CONTIROD® technology has achieved remarkable success through groundbreaking innovations in melting, casting, and rolling processes. This modularly structured system comprises a range of key components, including a shaft melting furnace, a holding furnace, a twin-belt caster, a rolling mill with separate individual drives, a deoxidation and cooling section, as well as a wire coil station, strapping unit, and foil packaging plant. The integrated process provides the advantage of inline melting, casting and rolling. From copper cathode to copper rod the thermal energy for melting is used in a very efficient way since all the process steps are combined in a row. CONTIROD® lines are available for annual capacities from 30,000 to 400,000 tonnes. These lines enable the production of ETP (Electrolytic Tough Pitch) or FRHC (Fire Refined High Conductivity) copper rod with a diameter range of 8 to 26 mm. Additionally, CONTIROD® plants are capable of producing copper alloys such as CuSn 0.3 or CuAg 0.1.

Boosting Efficiency through Technological Advancements

Thanks to the implementation of latest technological developments, the efficiency of the CONTIROD® system has been significantly increased. Key elements, such as the latest generation of the SMS shaft furnace with upgraded brickwork and newly developed nozzle mix burners, have played a crucial role in reducing energy consumption and ensuring stable working conditions. The utilization of 3D printing technology for the mixing elements in the new burners has improved the flame conditions. Additionally, the system now incorporates automatic flame monitoring along with the new burner technology. In addition to all these advantages in the standard configuration, the newly developed SMS nozzle-mix burner is hydrogen-ready! By embracing this innovation, the CONTIROD® system demonstrates its readiness to support sustainable practices in the industry.

The CONTIROD® process is the only CCR (Continuous Casting and Rolling) system that employs the twin-belt casting principle. This unique approach enables the production of a rectangular cast bar without bending during solidification, and opens the possibility of using a high amount of clean copper scrap.

The incorporation of high-pressure descaling in the finishing mill along with new high-pressure nozzle arrangements has an amazing effect in terms of the copper rod surface quality. Once again, the CONTIROD® process redefines the benchmark for copper rod quality, setting new standards in the industry.

The new treatment facilities for emulsion and cleaner, coupled with inline measurement and precise dosing, offers the benefit of reduced manual intervention. This leads to cost savings for consumables and makes the process easier to handle while maintaining a constant quality.

The latest generation cooling line is equipped with two cooling media systems. In the first phase, when the hot rod is guided from the rolling mill into the closed cooling tube system, it comes into contact with the cleaner agent system. Once complete de-oxydation is achieved, the rod is cooled down by a pure water cooling. To minimize compressed air consumption, the air wiper system at the end of the cooling line features a new 3D printed nozzle design. The new system reaches impressive savings of up to 70% of compressed air, further enhancing the overall efficiency of the process.

All these efforts combined with the array of SMS group digital products such as Smart Alarm, SMS-Metrics, Material Tracking, AIXpert as well as Scale-to-entire-process-chain, share one common goal: harnessing the advantages of CONTIROD® for a greener world and sustainable future!