Bearings and power transmission product distributor Bearings International (BI) is offering industrial equipment manufacturer ROCOL’s range of wire rope lubricant products to solve vital and complex lubrication challenges for local miners.

“Where lubricants are put through the most challenging environments involving extreme heat, load, vibration, water and dusty environments, ROCOL’s lubricants offer peace of mind and trustworthy performance,” says BI marketing manager Victor Strobel.

Despite lubrication being vital to the success of a mining operation, ensuring that mining equipment remains safe and operational, Strobel highlights that its importance is misunderstood.

He highlights wire rope lubricants as a significant part of BI’s ROCOL product offering, with other recently added products to the range that are also useful to mining customers.

Strobel emphasises the importance of the reduced toxicity of the ROCOL product, as traditional wire rope lubricants are toxic and difficult to apply, requiring complex and hazardous processes to prepare the lubricant.

Moreover, wire rope lubricants tend to “fling off” during use and drip onto floors and surfaces, which are safety risks.

Poor-performing wire rope lubricants do not penetrate and lubricate to the core of the wire rope, where frictional wear and corrosion are most dangerous because they are often invisible to the naked eye. This can lead to rope breakages, with serious implications for operational running costs, production output and safety.

“Not all wire rope lubricants are made equal. There are, in fact, dramatic differences in performance in the key areas mentioned among different wire rope lubricant manufacturers.”

In terms of other ROCOL products that assist with lubrication challenges in mining, Strobel cites dust-resistant bearing greases, as well as high-load greases for crushers, shakers, bucket pins, open gears and conveyors as being of importance.

For gearboxes, which run at high temperatures, the range includes a high-performance gearbox oil, designed to reduce frictional heat, wear and noise.

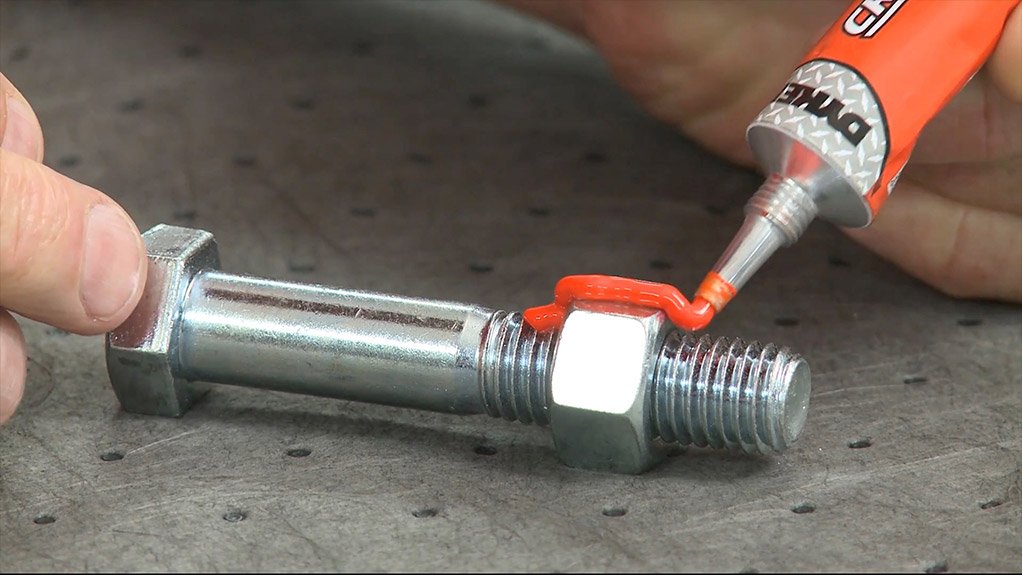

Further, BI added Cross Check – designed as a visual inspection method

to eliminate the re-torqueing of all types of fasteners on mining and earthmoving equipment –to its range in the middle of 2018.

The product is a wax seal for criticial holds and fastening, used as a tamper-proof torque mark. It is safe for most surfaces, highly visible, and is used to visually detect loose bolts and nuts.

This visual inspection method can help engineers, operators and foremen to do this, rather than using the conventional torque wrench which, Strobel notes, can be time consuming and labour intensive.

BI also offers the LPS 1 Greaseless Lubricant – an “ideal” product for mining and dusty environments. The fast-acting penetrating and lubricating spray does not attract dust or dirt, unlike traditional multi-purpose penetrating sprays, says Strobel.

“ROCOL meets the highest standards when it comes to the environment. It is ISO: 14 0001-accredited for environmental management systems. We have a range of biodegradable, environmentally acceptable lubricants and products for all types of mining.”

Strobel emphasises that ROCOL is known globally for its biodegradable wire rope lubricants, which offer higher performance than the non-biodegradable products which ROCOL supplies.

In addition, he highlights that ROCOL products are made from high-quality materials, to ensure the products last longer. This leads to increased productivity from fewer breakdowns, longer operational time between maintenance schedules, as well as overall savings for the end-user.

Local Mining Opportunities

Strobel states that BI supplies these products to the local coal, platinum, gold and diamond miners, owing to the unique nature of their operational footprint.

He cites that BI is supplying an owner of a large mine in the North West with ROCOL products to two of the mine’s shafts to assist in lengthening their life span while reducing maintenance costs.

The miner plans to use the same solution for its other shafts, adds Strobel.

Projects such as this remain a strategic segment for the company. It has 42 branches in South Africa, ensuring that its national footprint is close to major mining areas.

“We have focused on the mining segment for many years and have built good relations with customers in the sector.”

The company also aims to expand its product offering in the short to medium term to meet the increasing demands of the sector.

“Our team of certified technicians and product specialists is available to deliver a variety of on-site technical services to ensure operational efficiency and optimised plant uptime. BI’s field service offering is ideally located to quickly respond to our customer base,” he concludes.