The aluminium industry is undergoing a transformation driven by the need for sustainability, efficiency, and technological advancements.

At the forefront of this transformation, integrated service and solutions provider SMS group is dedicated to addressing the specific demands of its customers and local markets in the aluminium sector.

With a global presence, a diverse range of solutions, and a commitment to sustainable practices, SMS group is shaping the future of aluminium production, the company believes.

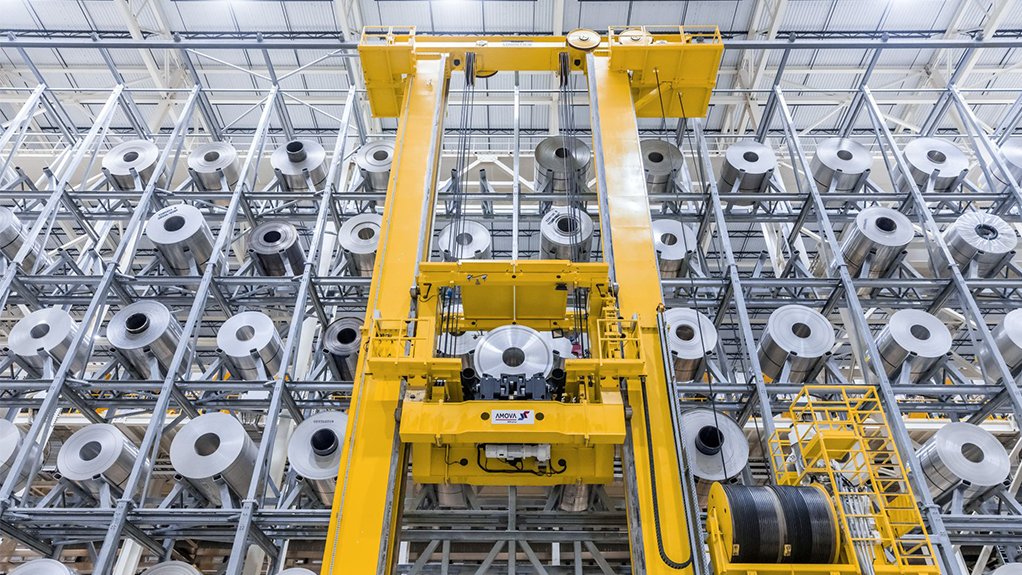

The company’s comprehensive approach, it explains, is exemplified by its presence in key regions worldwide, across a diverse customer base of manufacturing facilities, service workshops, and expert contacts.

By being where their customers need them, SMS group can “listen to their needs and provide advice on efficiency-enhancing concepts for new plant projects and upgrades”.

The company offers integrated solutions covering every stage of the aluminium production process, from the liquid phase to the finished product. This approach, delivered from a single source, includes life cycle partnership and long-term security.

Austrian firm Hertwich Engineering, a part of the SMS group, specialises in plant and machinery for the liquid phase of aluminium production.

The company’s Ecomelt furnaces exemplify its commitment to sustainability, as its furnaces recycle and melt aluminium scrap, burning off contaminants such as paints or oils.

The released energy is recycled and reused, thereby reducing demand for natural gas.

With an eye toward the future, Hertwich Engineering is prepared for the increased recycling of aluminium into the production cycle, offering advanced, energy efficient recycling furnaces, SMS group affirms.

In partnership with Iceland-based aluminium supplier Nordural, Hertwich Engineering is contributing to a zero-emissions project in the country’s aluminium sector.

Electrically heated holding furnaces, casters and automation systems – supplied by Hertwich –

will enable the production of low-carbon aluminium billets using renewable-energy sources. This initiative aligns with global climate targets and bears out the commitment to sustainable practices, SMS group says.

Further, the company highlights that established aluminium players, such as ElvalHalcor in Greece and LatemAluminium in Spain, are “prime examples” of SMS group’s support for manufacturers of flat products.

“These companies received advanced finishing lines and cold rolling mills from SMS group, enhancing their production capabilities and expanding their market presence.”

The dry strip (DS) system – developed by SMS group – introduces an efficient, contact-free method for removing rolling emulsion residues from strip surfaces. Installed in the exit of a cold rolling stand, the system prevents stain spots, optimising surface quality and productivity.

With its blend of stationary and movable sealing elements and precisely balanced blow-off and extraction areas, the DS system showcases SMS group’s commitment to technological innovation, the company says.

Meanwhile, SMS group’s single-stand cold rolling mills (CRMs) are engineered to handle a wide range of aluminium grades and thin strip products.

These CRMs cater to hard grades, addressing the evolving needs of the aluminium industry.

These technologies also refer to flat products, the company adds.

Additionally, the group’s acquisition of Italian companies OMAV S.p.A. and Hydromec S.R.L. has bolstered its capabilities in the extrusion and forging press markets.